Jahr

Year | Titel/Autor:in

Title/Author | Publikationstyp

Publication Type |

|---|

| 2026 |

Echo cancellation for ultrasonic flaw detection behind reverberating layers

Schäfer, Marius; Rabe, Ute; Fischer, Sarah C.L. |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

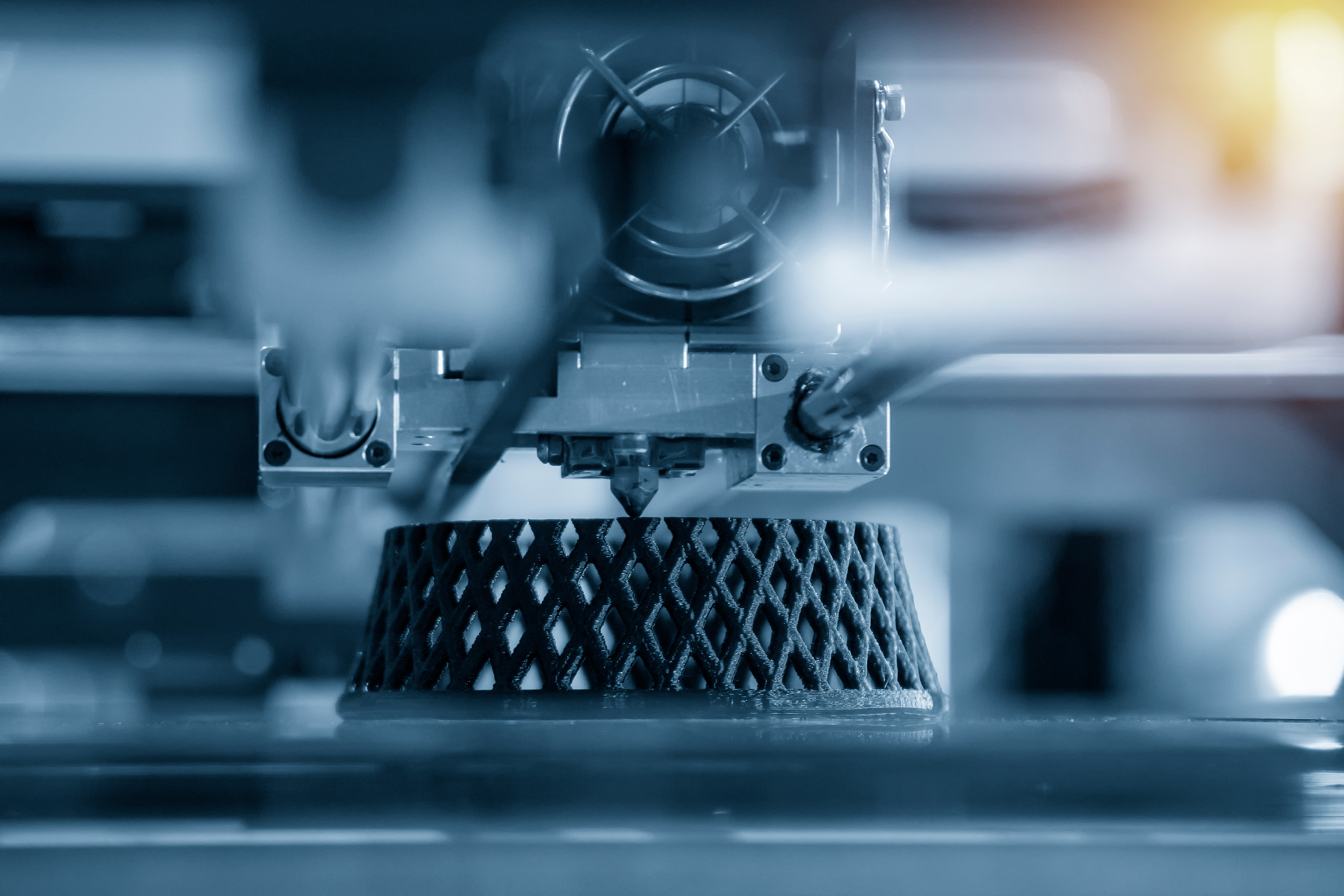

Simulation-based approach to estimate influencing factors on acoustic resonance spectra of additively manufactured mechanical metamaterials

Boyadzhieva, Silviya M.; Gutmann, Florian; Fischer, Sarah |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Entwicklung und Charakterisierung einer programmierbaren vibroakustischen Einheitszelle zum gezielten Einstellen von Dämpfungseigenschaften

Kollmannsperger, Lea Sophie; Kaal, William; Becker, Michael; Fischer, Sarah |

Konferenzbeitrag

Conference Paper

|

| 2024 |

Untersuchung des Einsatzes von akustischer Überwachung in einem Assistenzsystem für die Schweinehaltung

Bollmann, Katharina; Nicolaisen, Thies J.; Ganster, Michael; Herter, Simon; Hennig-Pauka, Isabel; Fischer, Sarah |

Konferenzbeitrag

Conference Paper

|

| 2024 |

Evaluation of a Local Acoustic Resonance Method for Coating Thickness Determination on Stochastic Metal Hybrid Foams

Kollmannsperger, Lea Sophie; Kunz, Francesco; Becker, Michael; Jung, Anne; Fischer, Sarah C.L. |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Soft Tactile Coil-Based Sensor for Misalignment Detection of Adhesive Fibrillary Gripping Systems

Herter, Simon; Stopp, Philipp; Fischer, Sarah |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Akustische Freifeldeigenschaften komplexer Materialsysteme im geschlossenen Akustik-Rohr

Becker, Michael; Kollmannsperger, Lea Sophie; Fischer, Sarah |

Konferenzbeitrag

Conference Paper

|

| 2024 |

Acoustic Nondestructive Characterization of Metal Pantographs for Material and Defect Identification

Boyadzhieva, Silviya M.; Kollmannsperger, Lea Sophie; Gutmann, Florian; Straub, Thomas; Fischer, Sarah |

Konferenzbeitrag

Conference Paper

|

| 2024 |

Akustische Charakterisierung des Schädigungsverhaltens von AlSi10Mg-LPBF-Gitterstrukturen unter zyklischer Belastung

Kollmannsperger, Lea Sophie; Fischer, Sarah |

Konferenzbeitrag

Conference Paper

|

| 2024 |

Modular, Physically Motivated Simulation Model of an Ultrasonic Testing System

Schäfer, Marius; Fischer, Sarah |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Acoustic emission of lattice structures under cycling loading relates process parameters with fatigue properties

Kollmannsperger, Lea Sophie; Maurer, Oliver; Kose, Rebecca; Zeuner, André Till; Bähre, Dirk; Fischer, Sarah |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Soft Tactile Coil-Based Sensor for Misalignment Detection of Adhesive Fibrillary Gripping Systems

Herter, Simon; Stopp, Philipp; Fischer, Sarah |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Identifying Factors Influencing the Properties of Vibroacoustic Metamaterials Using Three Different Acoustic Methods

Kollmannsperger, Lea Sophie; Kaal, William; Becker, Michael; Fischer, Sarah |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Remanent Magnetic Field Scanning of Coating‐Graded Hybrid Foams

Kunz, Francesco; Ibrahim, Bashar; Becker, Michael; Gao, Haibin; Fischer, Sarah; Jung, Anne |

Zeitschriftenaufsatz

Journal Article

|

| 2024 |

Inverse stimulation enables ultrasonic binary coding for NDE using a custom linear testing system

Schäfer, Marius; Fischer, Sarah |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Influence of the Dross Formation of the Laser-Cut Edge on the Fatigue Strength of AISI 304

Bach, Julia; Zeuner, André; Wanski, Thomas; Fischer, Sarah; Herwig, Patrick; Zimmermann, Martina |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Controlling Malleability of Metamaterials through Programmable Memory

Wenz, Franziska; Schönfeld, Dennis; Fischer, Sarah; Pretsch, Thorsten; Eberl, Christoph |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Ultraschallbasierte in situ Vorspannkraftermittlung an Schrauben ohne Referenzmessung im nicht verspannten Zustand durch Kombination von Longitudinal- und Transversalwellen

Niwinski, Thomas Jerzy; Kraemer, Frank; Klein, Marcus; Oechsner, Matthias; Herter, Simon; Becker, Michael |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Characterization of Filigree Additively Manufactured NiTi Structures Using Micro Tomography and Micromechanical Testing for Metamaterial Material Models

Straub, Thomas; Fell, Jonas; Zabler, Simon; Gustmann, Tobias; Korn, Hannes; Fischer, Sarah |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Design framework for programmable mechanical metamaterial with unconventional damping properties under dynamic loading conditions

Kaal, William; Becker, Michael; Specht, Marius; Fischer, Sarah |

Zeitschriftenaufsatz

Journal Article

|

| 2023 |

Evaluation of the bi Wave Method for Ultrasound Preload Determination in the Field with Machine Learning

Herter, Simon; Becker, Michael; Fischer, Sarah |

Konferenzbeitrag

Conference Paper

|

| 2023 |

Influence of a Pronounced Pre-Deformation on the Attachment of Melt Droplets and the Fatigue Behavior of Laser-Cut AISI 304

Zeuner, André Till; Wanski, Thomas; Schettler, Sebastian; Fell, Jonas; Wetzig, Andreas; Kühne, Robert; Fischer, Sarah; Zimmermann, Martina |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Design and Manufacturing of a Metal-Based Mechanical Metamaterial with Tunable Damping Properties

Kappe, Konstantin; Wahl, Jan P.; Gutmann, Florian; Boyadzhieva, Silviya; Hoschke, Klaus; Fischer, Sarah |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Vorspannkraft-Monitoring mittels Ultraschallmethoden ohne Referenzmessung

Herter, Simon; Niwinski, Thomas; Klein, Marcus; Oechsner, Matthias; Becker, Michael |

Zeitschriftenaufsatz

Journal Article

|

| 2022 |

Thermoresponsive Programmable Materials

Pretsch, Thorsten; Chalissery, Dilip; Schönfeld, Dennis; Walter, Mario; Andrä, Heiko; Wenz, Franziska; Eberl, Christoph; Weisheit, Linda; Ziervogel, Fabian; Fischer, Sarah |

Vortrag

Presentation

|

| 2021 |

Sichere Offshore-Schraubenverbindungen - verlässliche Überwachung der Vorspannkraft mit Ultraschall

Herter, Simon; Niwinski, Thomas; Klein, Marcus; Becker, Michael M. |

Bericht

Report

|

| 2021 |

Optimization of the Unambiguity of Cross-Correlated Ultrasonic Signals through Coded Excitation Sequences for Robust Time-of-Flight Measurements

Schäfer, Marius; Theado, Hendrik; Becker, Michael M.; Fischer, Sarah C.L. |

Zeitschriftenaufsatz

Journal Article

|

| 2021 |

Machine Learning Based Preprocessing to Ensure Validity of Cross-Correlated Ultrasound Signals for Time-of-Flight Measurements

Herter, Simon; Youssef, Sargon; Becker, Michael M.; Fischer, Sarah C.L. |

Zeitschriftenaufsatz

Journal Article

|

| 2020 |

Nondestructive Characterization of Residual Stresses Using Micromagnetic and Ultrasonic Techniques

Rabung, Madalina; Amiri, Meisam; Becker, Michael M.; Kopp, Melanie; Tschuncky, Ralf; Veile, Ines; Weber, Fabian; Weikert-Müller, Miriam; Szielasko, Klaus |

Aufsatz in Buch

Book Article

|

| 2020 |

Mechanical metamaterials on the way from laboratory scale to industrial applications: Challenges for characterization and scalability

Fischer, Sarah C.L.; Hillen, Leonie; Eberl, Christoph |

Zeitschriftenaufsatz

Journal Article

|

| 2020 |

Rückführbare Überprüfung von Ultraschall-Eigenspannungsprüfsystemen für klotzgebremste Eisenbahnräder am Beispiel des neuen UER-mobil Prüfsystems

Becker, Michael; Schuchhardt, Jörg |

Konferenzbeitrag

Conference Paper

|

| 2018 |

Numerical study of resonant frequencies in multi-material microstructures excited by ultrasonic vibrations

Becker, Michael M.; Fischer, Sarah C.L.; Arzt, Eduard; Rabe, Ute |

Konferenzbeitrag

Conference Paper

|

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP