A method for powder characterization is being developed to improve the quality and reduce the post-treatment of additively manufactured components and to increase the efficiency of the manufacturing process. Components from additive manufacturing processes often exhibit defects in the form of pores and voids, which are located both inside the component and on its surface and can have a very negative effect on the mechanical properties. By increasing the powder density during the manufacturing process, it is possible to reduce the pore density in the components. Mechanical vibrations are one way of increasing the powder density.

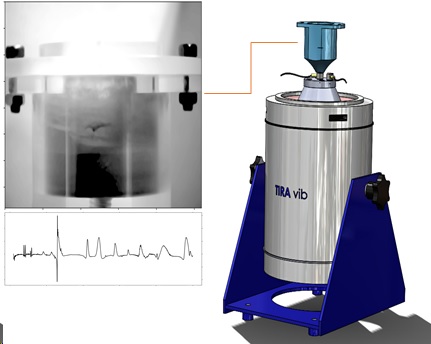

The vibrations are generated using an electrodynamic shaker; their effect on the powder compaction properties is being investigated. Effective control and precise measurement of the powder vibration is essential to determine the state of the powder and its mechanical behavior during excitation.

Furthermore, vibration frequencies, amplitudes, powder properties and material are varied and their influences on compaction are analyzed. In addition, other parameters that are also relevant, such as the type of excitation (sinusoidal, noisy, pulsed, etc.), powder mass, particle size, shape and composition are taken into account.

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP