In the railroad industry and many other industrial sectors, nondestructive 100 percent in-process examination of safety relevant components like railroad wheels for surface-breaking cracks is mandatory. In future, nondestructive testing techniques are preferred for this purpose that don´t need any previous surface preparation. Additional requirements are high sensitivity, reliability and objectivity plus eligibility for full automation.

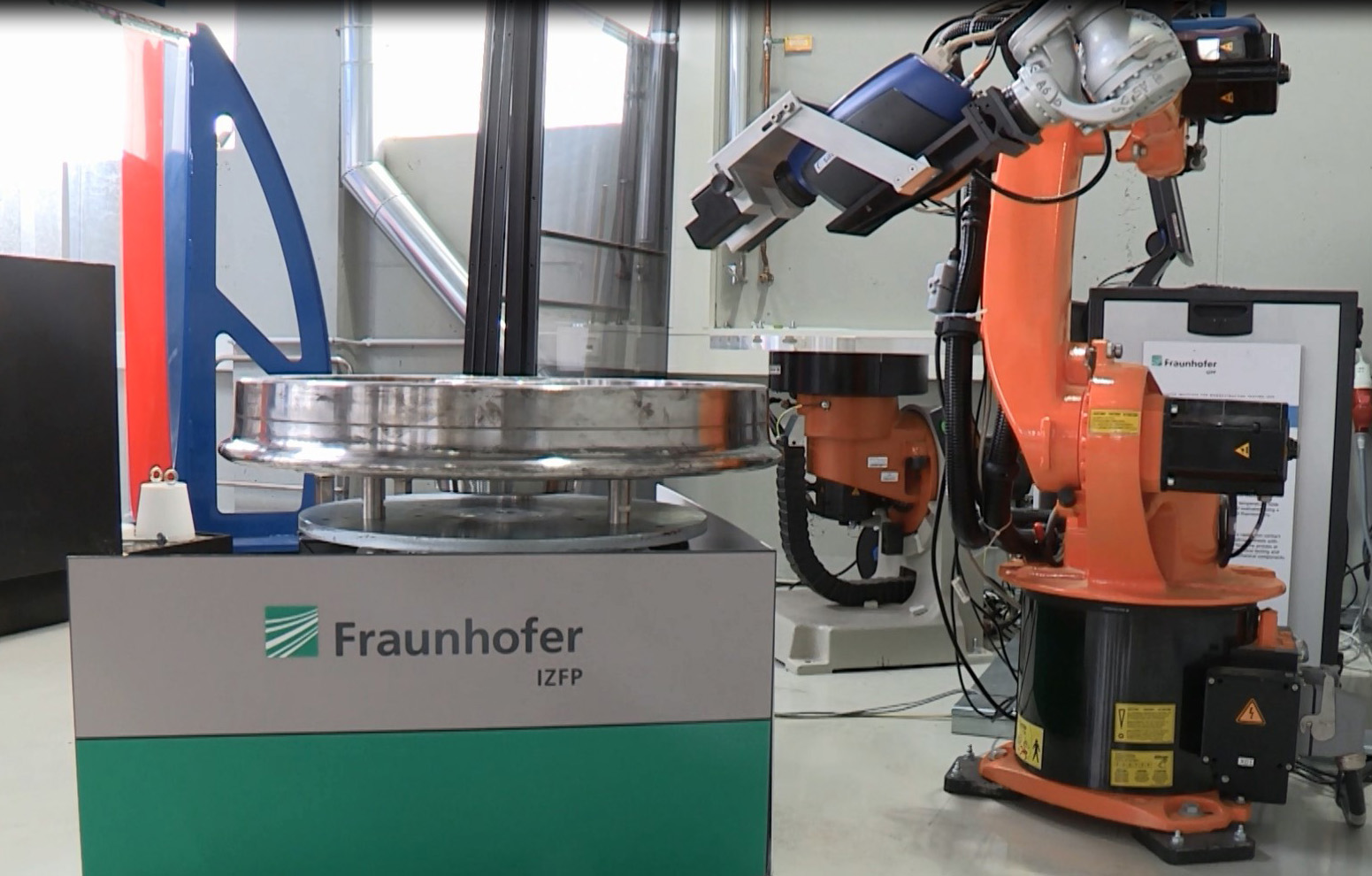

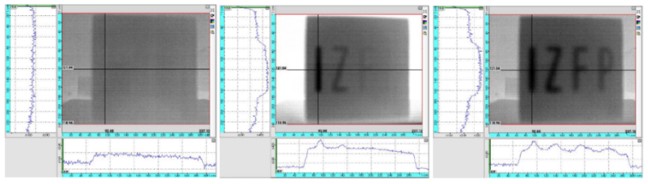

Induction thermography works fast and allows the detection of surface cracks in steel components without the need for prior surface preparation. The method can easily be automated without large efforts regarding the mechanics. It is sensitive, reliable and objective and provides the ability to determine the defect depth. Therefore, it is very well suited for fully automated test systems integrated in the production line for 100 percent testing.

Fraunhofer IZFP has the technical equipment for different excitation variants of active thermography: Optical pulse and “lock-in“ excitation (periodic excitation)

- Ultrasonic excitation and inductive excitation by electromagnetic alternating fields

- Different infrared camera systems for the near, medium and long-wave infrared radiation range providing a non-contact infrared technology

- Temperature resolution up to 15 mK

- Time resolution up to 50 microseconds

- Frame rates up to 20 kHz and

- Resolutions up to 1024 × 768 pixels

- Temperature resolution up to 15 mK

- Robots and linear mechanical devices for fast, automated testing

- Specialized software to perform

- Control of inspection systems data

- Processing and analysis of measured data

- Automated defect detection and defect reconstruction

- Control of inspection systems data

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP