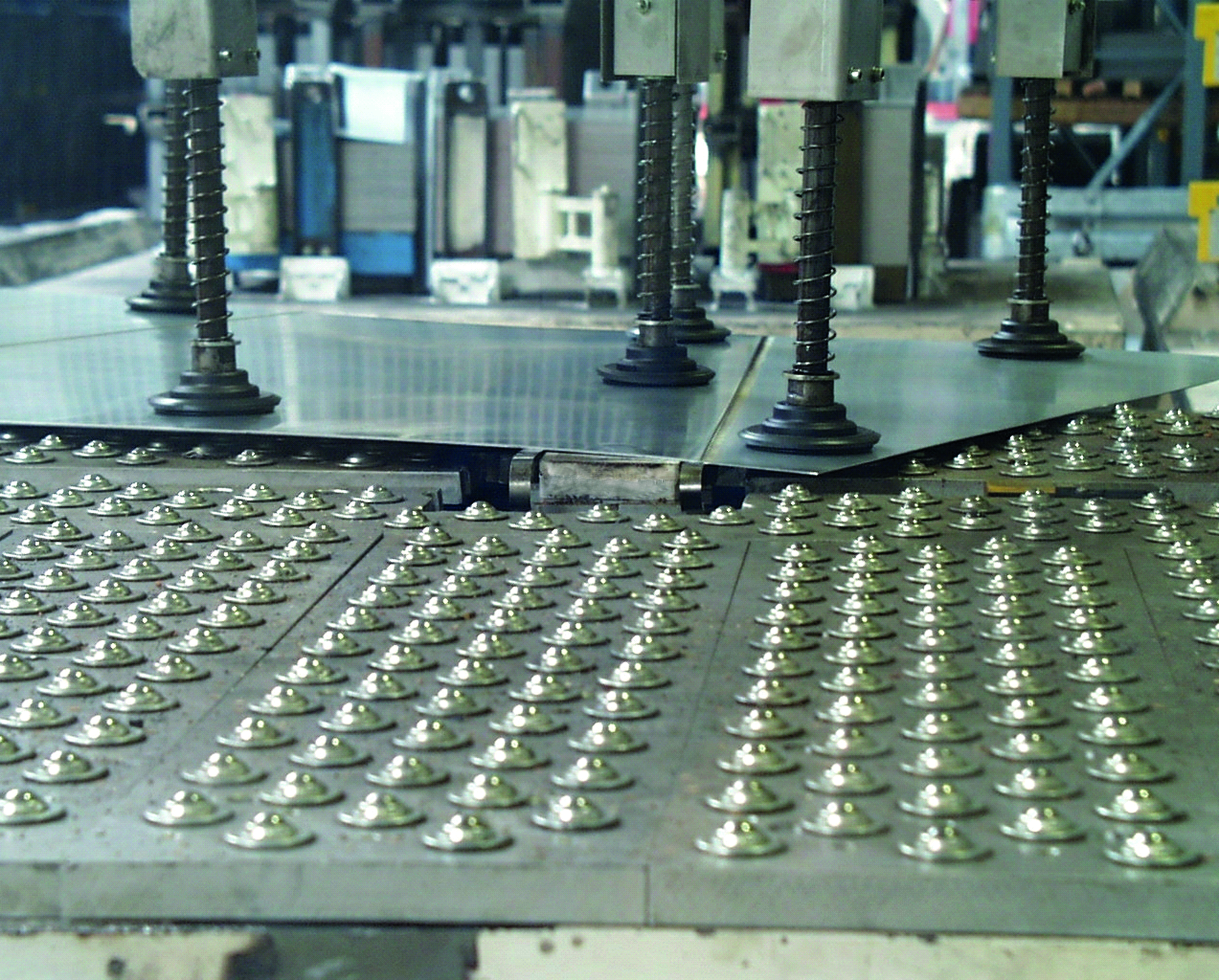

Ultrasonic inspection with its various techniques has long been a central procedure of nondestructive testing and thus an essential element of many quality assurance measures. In most if not all sections of the product lifecycle - but particularly for production processes - it provides established methods with versatile possibilities to guarantee the safety of the manufactured products.

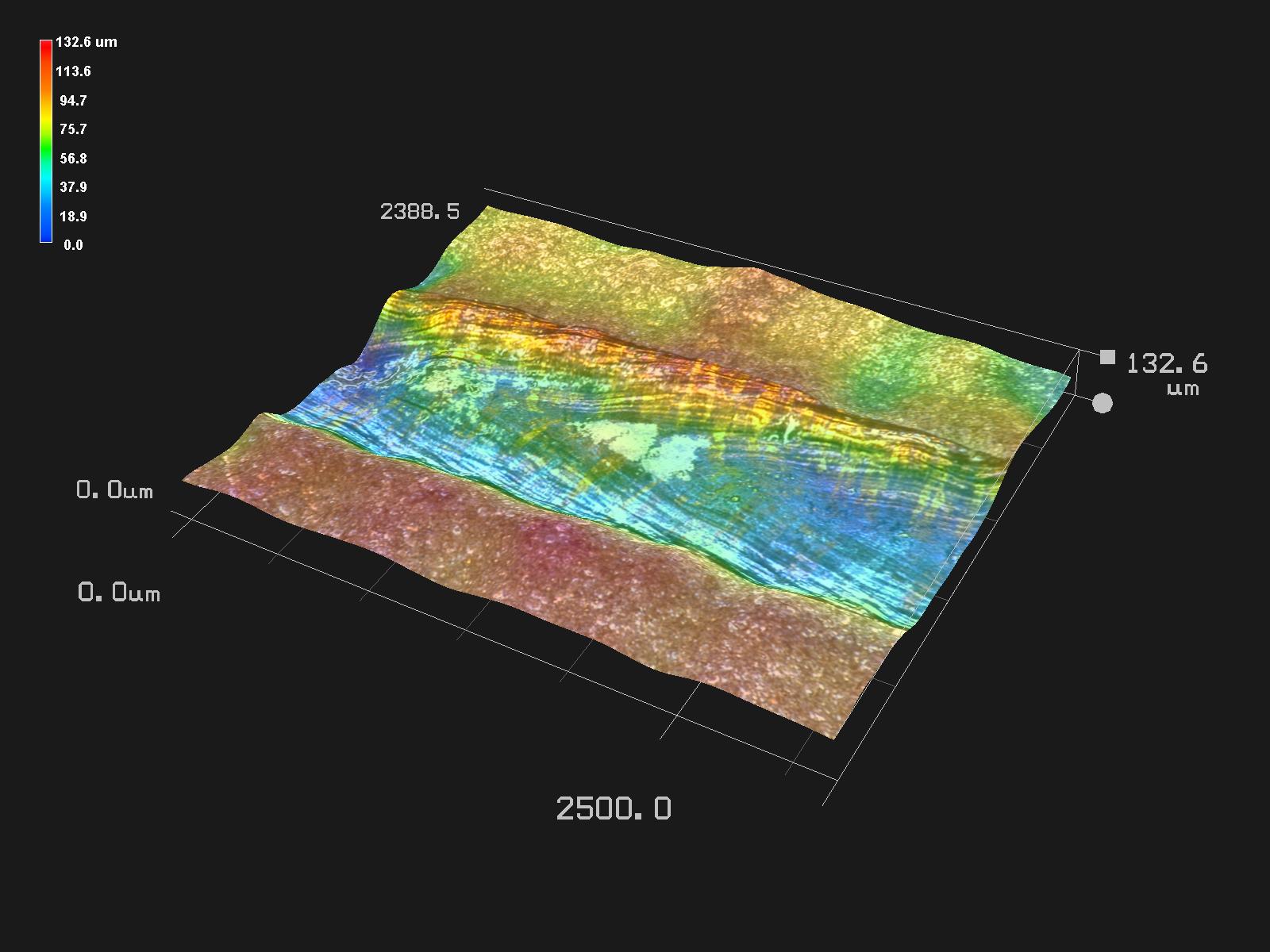

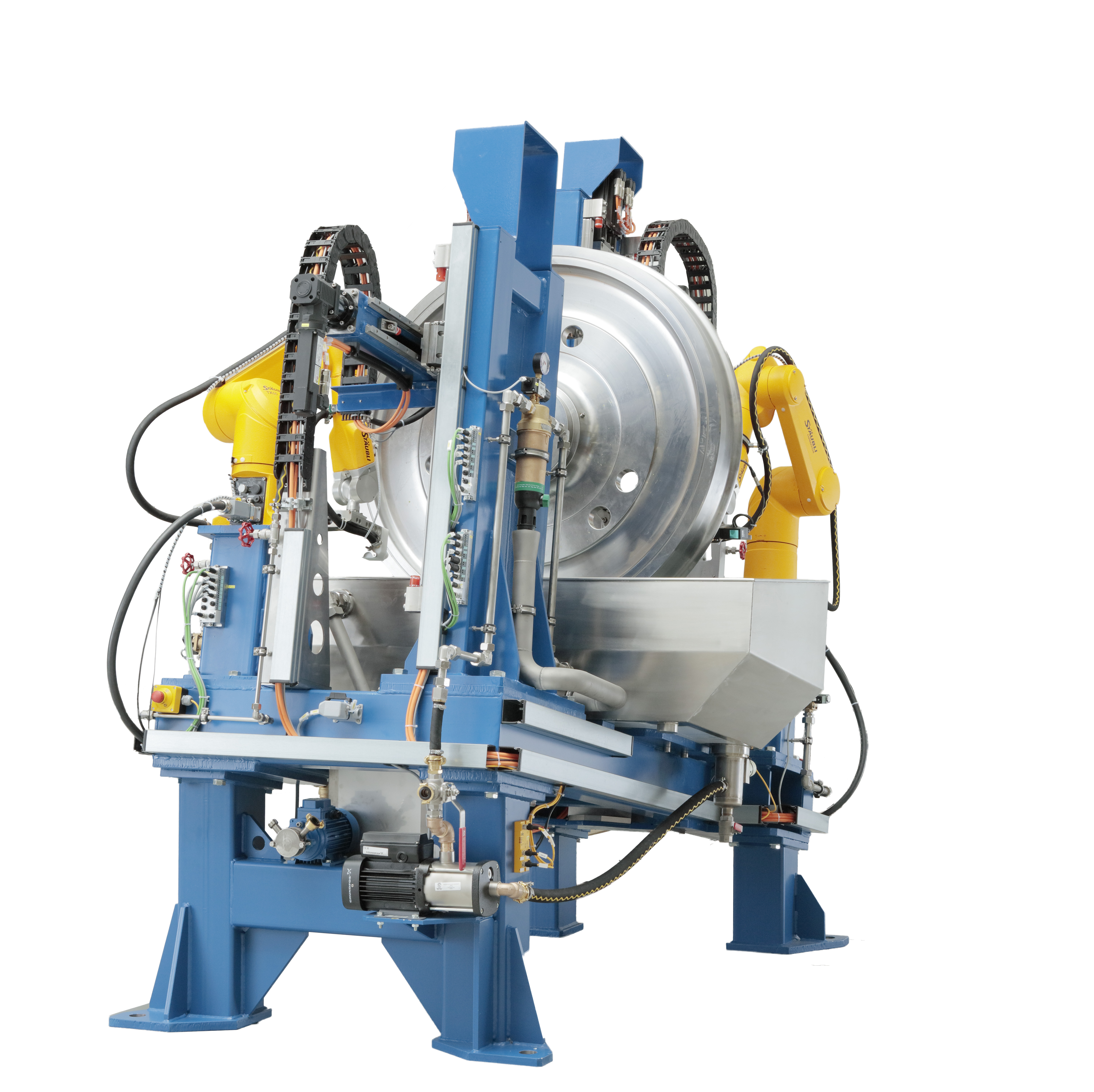

By the rise of novel materials such as fiber-reinforced plastics, high-strength steels and light metals, which are used alone or in combination in hybrid components and as composite materials, the requirements for ultrasound inspection have significantly increased over the last decade. These material-related challenges are intensified by increasingly complex component geometries, the need for high-resolution defect detection or the realization of faster inspection speed. All this can be taken into account with the methods provided at Fraunhofer IZFP. The areas of material characterization, component / assembly inspection and condition monitoring are the focus of our attention.

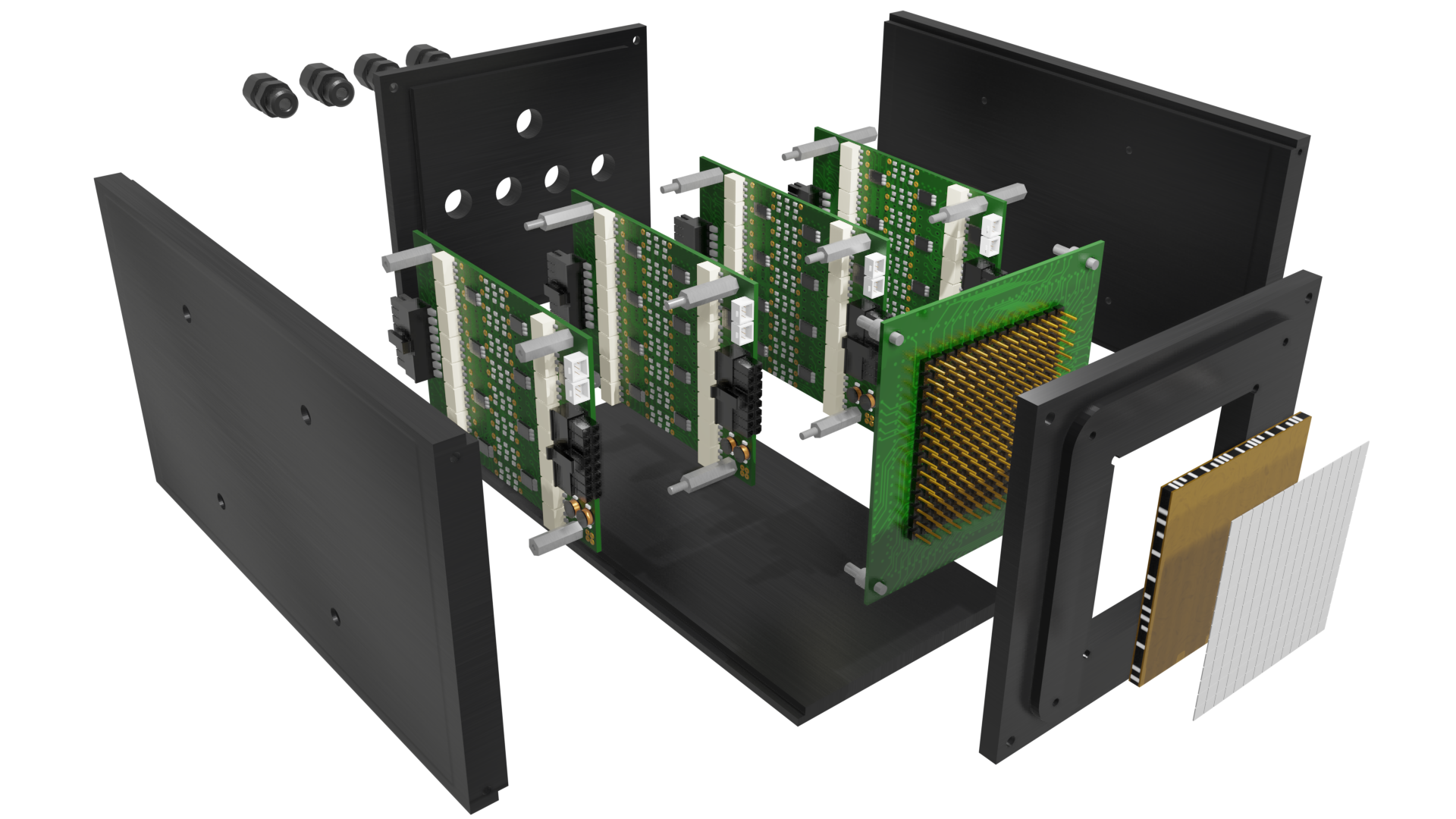

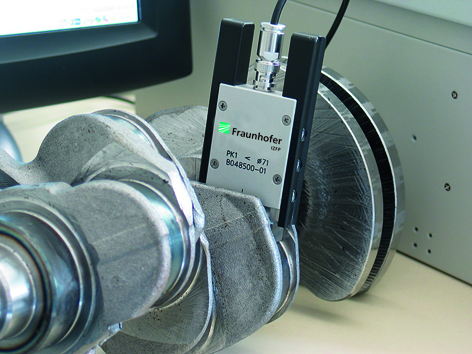

The institute has a wide range of application-oriented techniques, competences and know-how at its disposal. This comprises, among other things, the construction of specially adapted ultrasound transducers and inspection systems including hardware and software development as well as the execution of qualifying manual and robot-based ultrasound tests to meet customer-specific requirements.

In addition, Fraunhofer IZFP counsels its customers in the preparation of specific inspection instructions and supports the execution and the evaluation of inspections.

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP