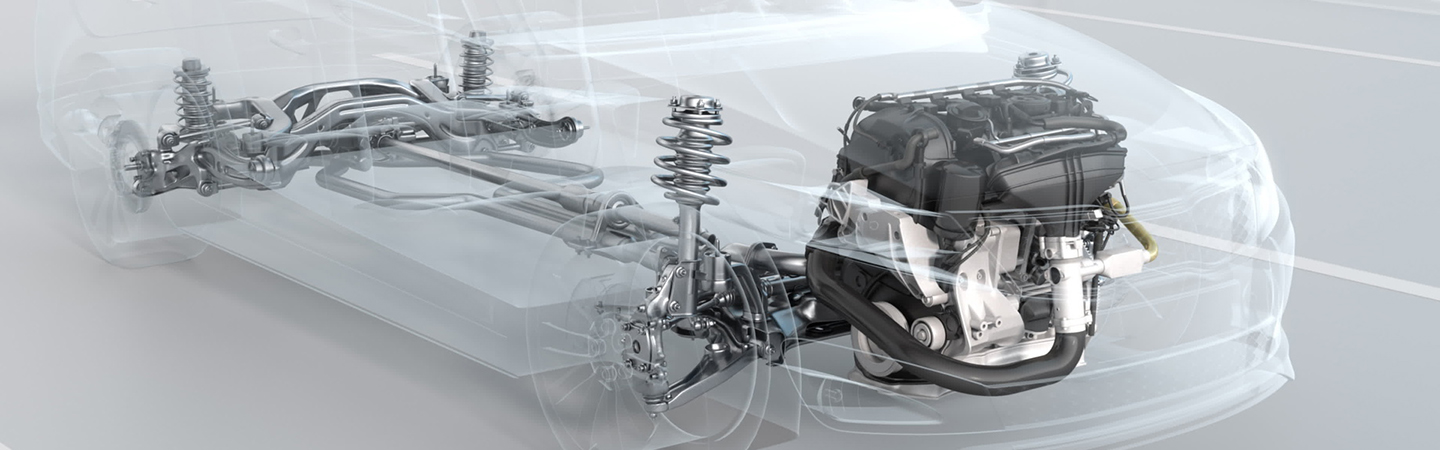

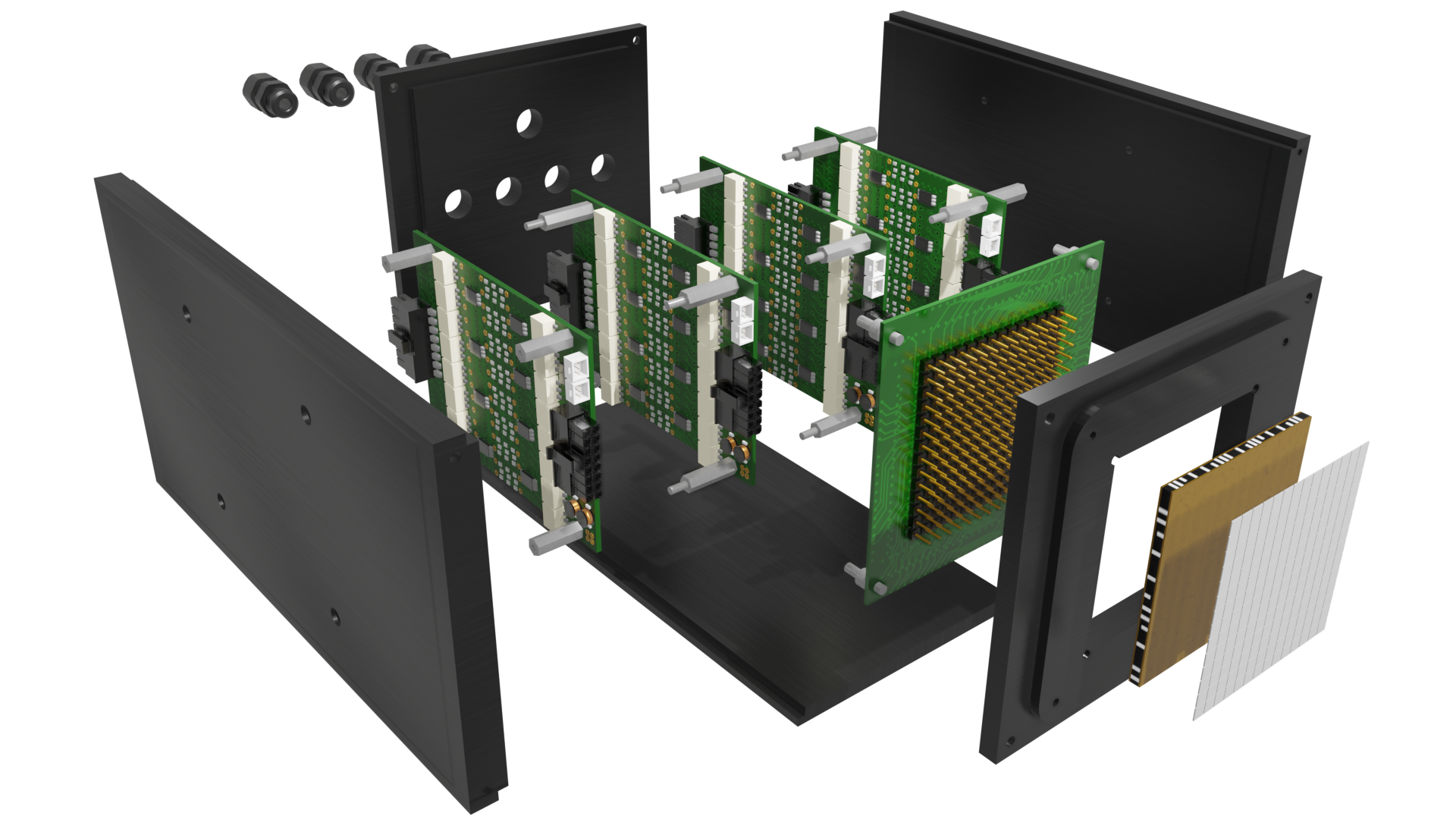

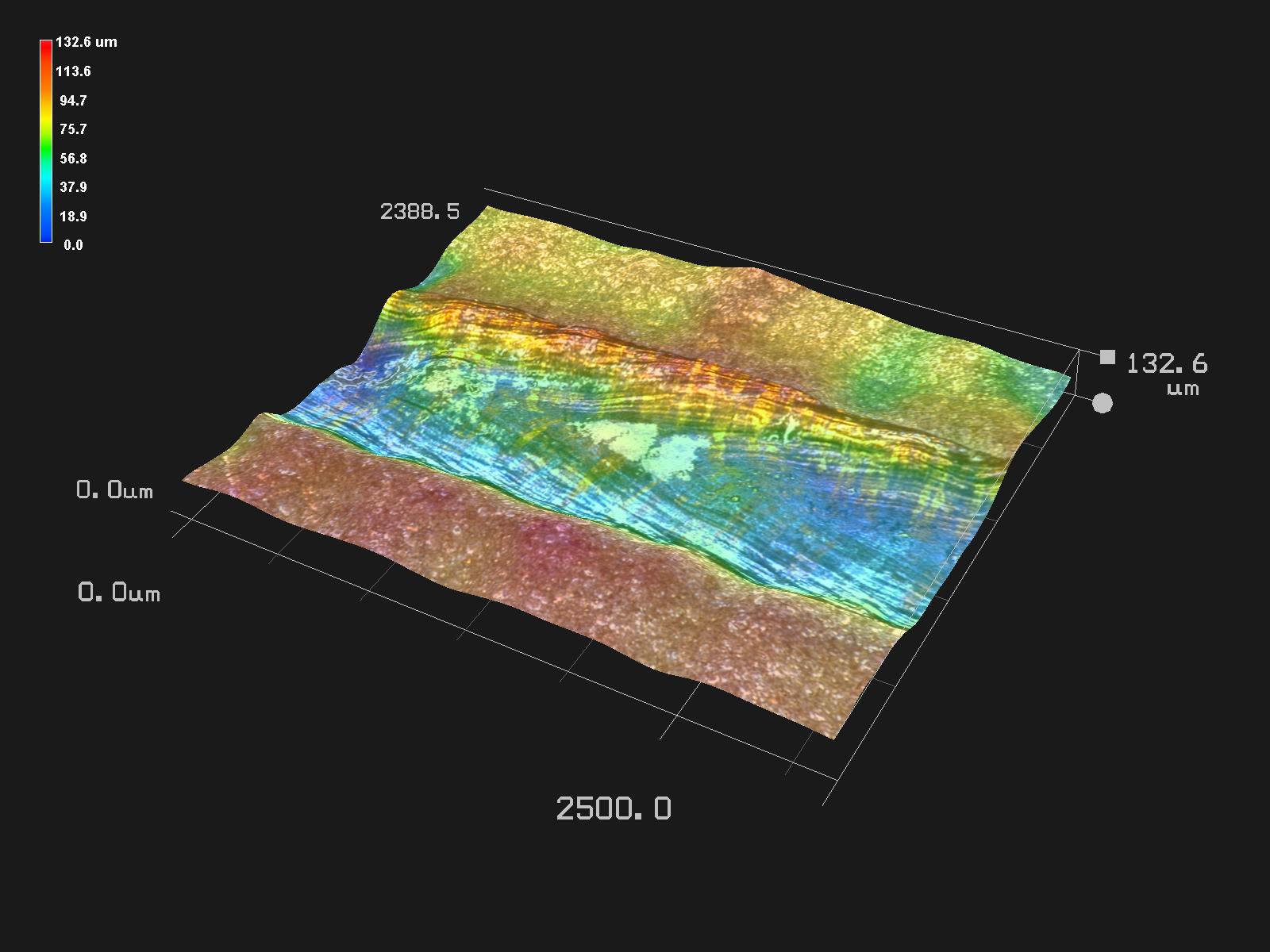

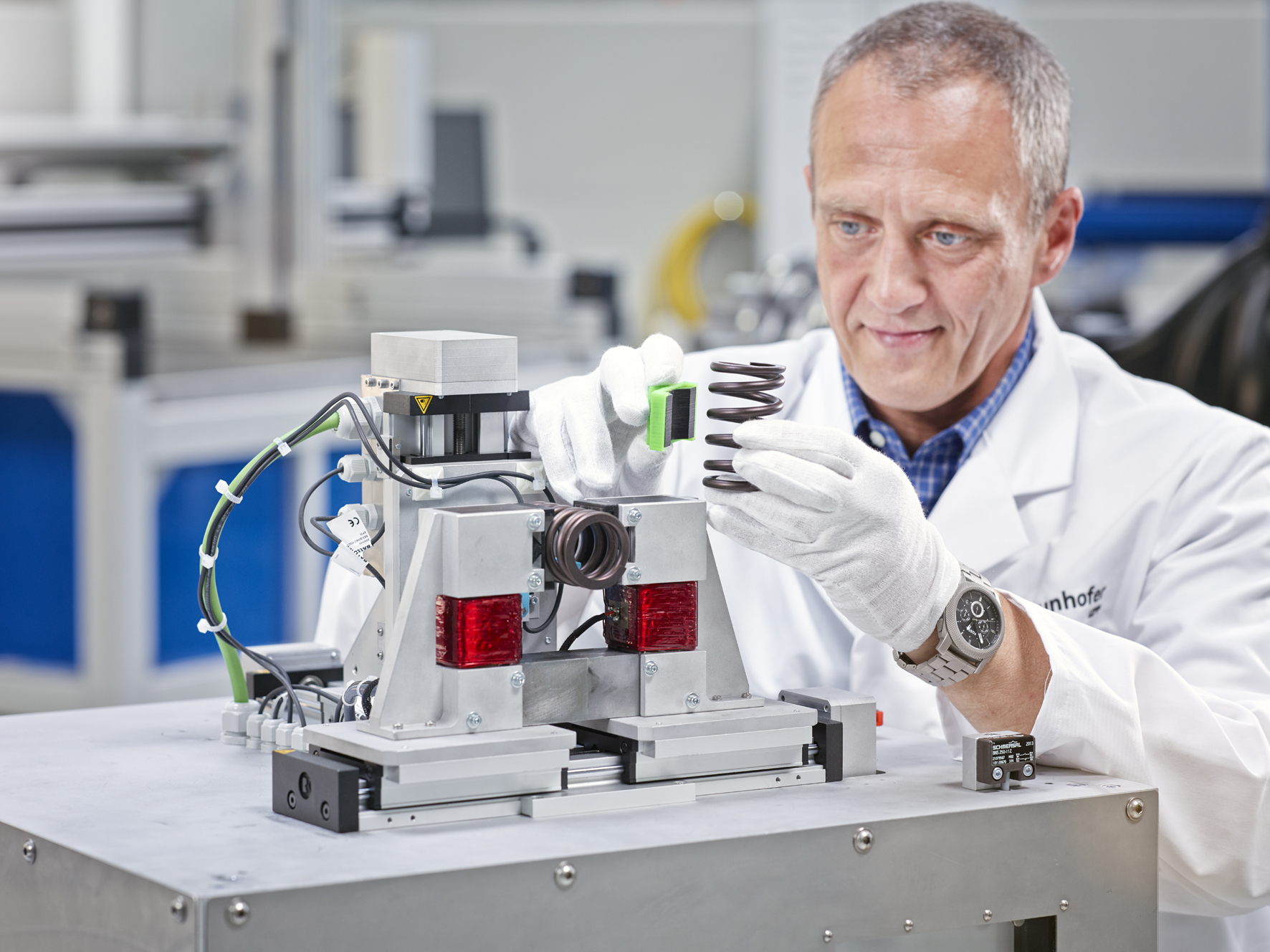

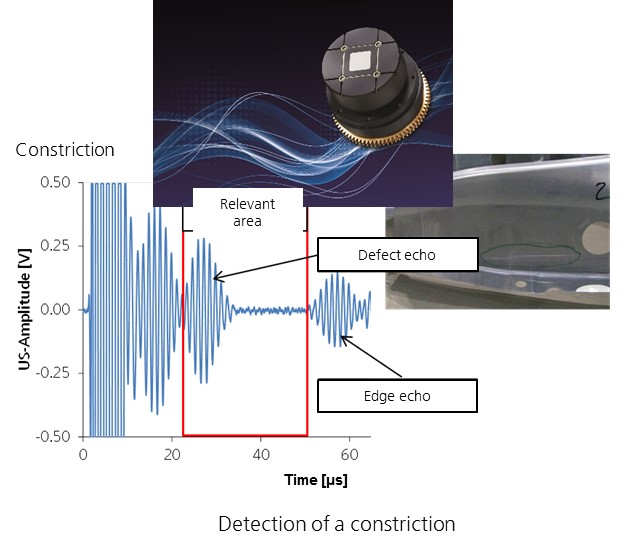

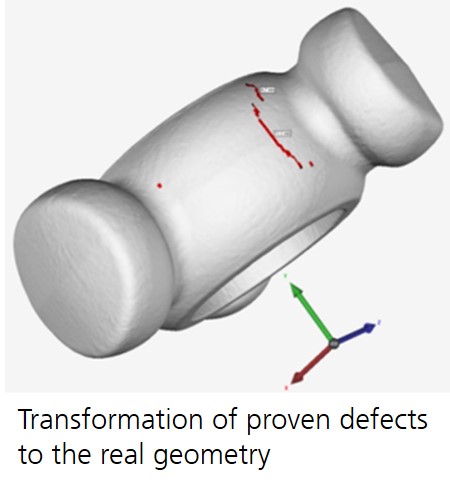

A major task of the business field "automotive" is to support car manufacturers as well as supplier industry in testing new materials and products fast and reliably by means of nondestructive methods. Early inclusion of NDT design into the development process provides high potential of cost efficiency at concurrently enhanced product quality by adequate inspection scheduling. Thematic work is concerned, amongst others, with the inspection and process control of hardness and mechanical-technological properties, defect inspection of ultra-high-strength steels or NDT for bonding technologies of metals and platics as well as hybride materials.

Also, in later phases of the product life cycle or in case of damage and subsequent repairing solutions for testing and assessing assemblies and structures are highly needed, especially in case of new materials.

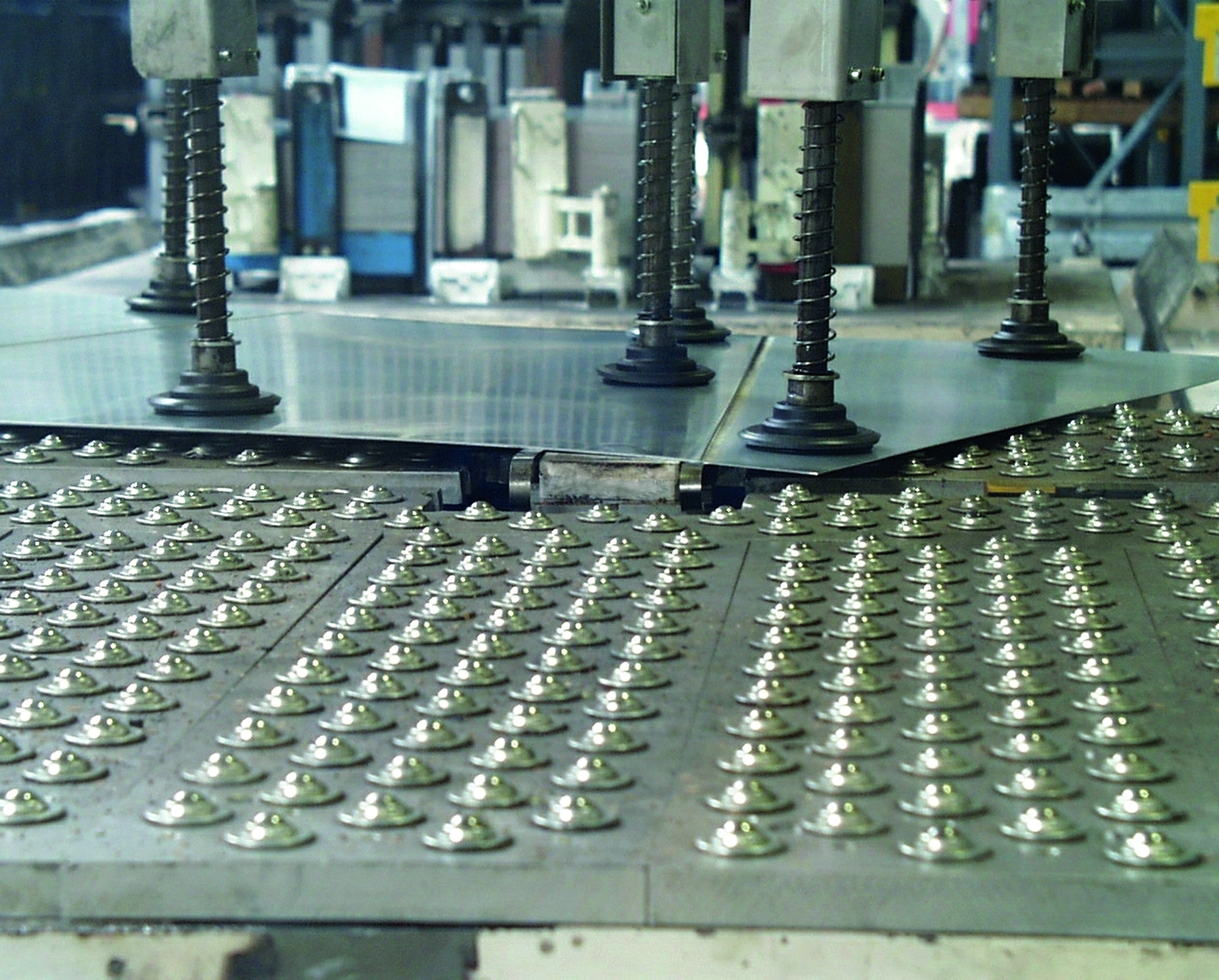

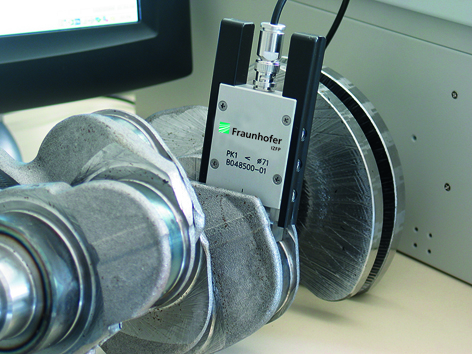

The diversity of materials used in automotive industry steadily rises. However, specific material properties can only be exploited in an optimal way if eligible joint technologies are on hand, e.g. glueing methods, thermal methods such as friction stir welding, laser welding and laser soldering, or mechanical procedures such as hemming and clinching. Covering all these methods Fraunhofer IZFP has long-term experience in developing inspection technologies for reliable, nondestructive joint quality assurance.

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP