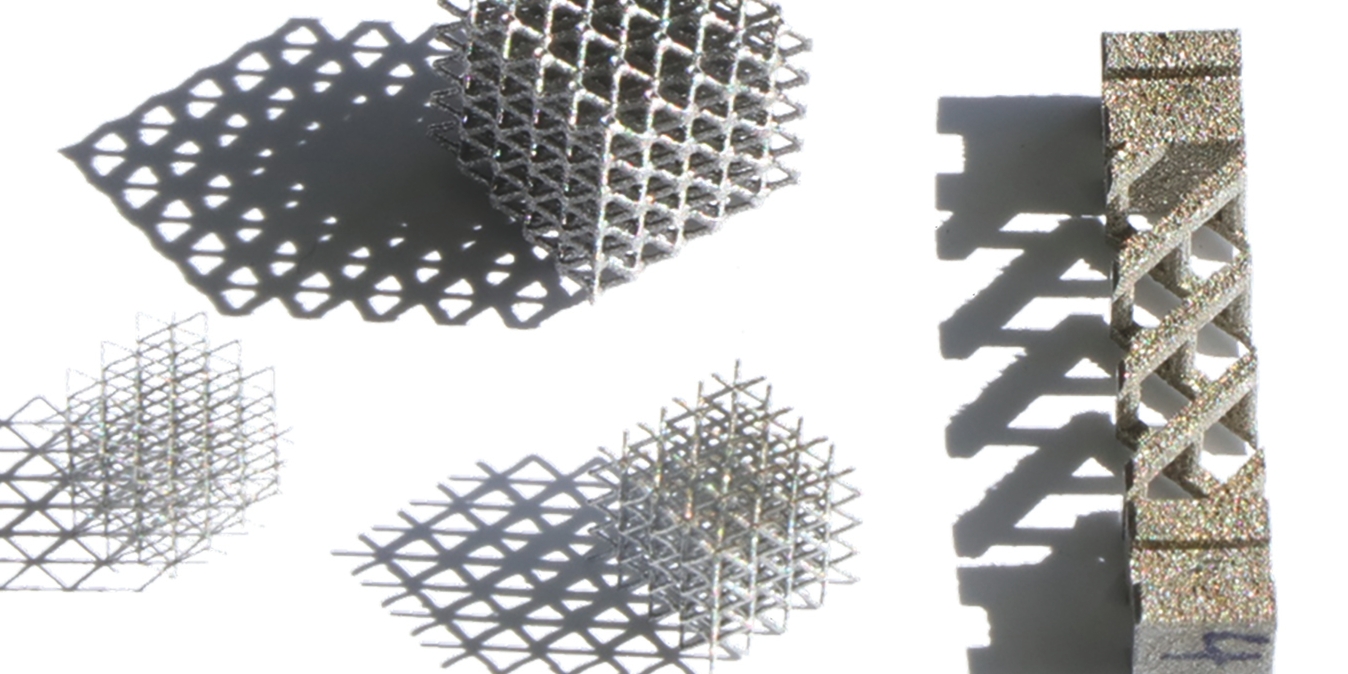

Mechanical metamaterials have great potential due to their extraordinary properties. They offer enormous scope for design, but due to their structural hierarchies, they require new ways of developing and describing materials. The already complicated relationship between processing, microstructure and properties becomes even more complex with these materials, as their mechanical properties depend on the structures of functional elementary cells on the mesoscale.

Currently, the main goal of research and development of mechanical metamaterials is to achieve the desired functionalities. This certainly shows the potential of mechanical metamaterials, but many other aspects with high relevance for technical applications are still neglected. The reliability of mechanical metamaterials is a prerequisite for industrial applications and has not been the focus of research so far. In order to obtain reliable metamaterials, relevant properties such as strength, fracture toughness and fatigue behavior must be taken into account.For complex materials such as metamaterials, the design of characterization strategies along the product life cycle is crucial:

Characterization during the manufacturing process is a promising approach, especially for additive manufacturing where parts are produced incrementally. Monitoring techniques should capture online deviations caused by process and machine errors and ideally provide an immediate three-dimensional representation of defects as well as statements about effects on component properties.The characterization after manufacturing is equally important for the characterization of the product and as a basis for monitoring issues as well as for the quality characteristics that can be used to assess the remaining lifetime of metamaterial products.

Computational methods and algorithms play an important role in understanding the collected data and correlating it with physical effects. Advanced methods of data fusion and the use of artificial intelligence methods are seen as key to linking data together and creating more meaningful information.

Understanding the resilience of mechanical metamaterials will be crucial if they are to become more than lab-scale materials. Therefore, in addition to the design and development of mechanical metamaterials, suitable non-destructive characterization methods need to be developed. A combination of different classical characterization methods - combined with advanced computational methods - is needed to correlate the quality and functionality of parts. This multimodal approach is not identical for every metamaterial, as the properties to be determined are application-specific. A suitable toolbox of methods will form the basis for scaling mechanical metamaterials in industrial applications.Consideration of the general relationships described is essential in order to produce metamaterials that are reliable and suitable for industrial applications. All these properties are not just properties of a metamaterial system, but the superposition of all its design properties as well as intrinsic tolerances and defects. For metamaterials to revolutionize the industry, design must move away from a focus on pure functionality to consider aspects of reliability and minimize the impact of any anomalies that occur.

The dream of revolutionizing industrial applications through metamaterials has not yet been realized. Much more effort is needed to fully understand the interactions of different design parameters and failures in mechanical metamaterials and make them an integral part of the product development process. Only then will major innovations based on metamaterials become a reality in novel industrial, transportation, lifestyle or household products.

More information can be found in the publication "Mechanical Metamaterials on the Way from Laboratory Scale to Industrial Applications: Challenges for Characterization and Scalability" by Sarah Fischer et al. (DOI: 10.3390/ma13163605) .

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP