Fraunhofer IZFP and Tongji University launch international cooperation for high-speed trains

November 6, 2025

October 1, 2025, marked the launch of the “Fraunhofer Innovation Platform for Intelligent Transportation and Mobility Monitoring FIP-ITMM@TONGJI”. The cooperation between the Fraunhofer Institute for Nondestructive Testing IZFP and Tongji University in Shanghai, China, is developing a range of services for smart predictive maintenance and intelligent monitoring systems in high-speed rail transport. The cooperation gives Fraunhofer IZFP access to the world's largest high-speed network and to the test infrastructure at the partner organization and will run for five years. Please read more...

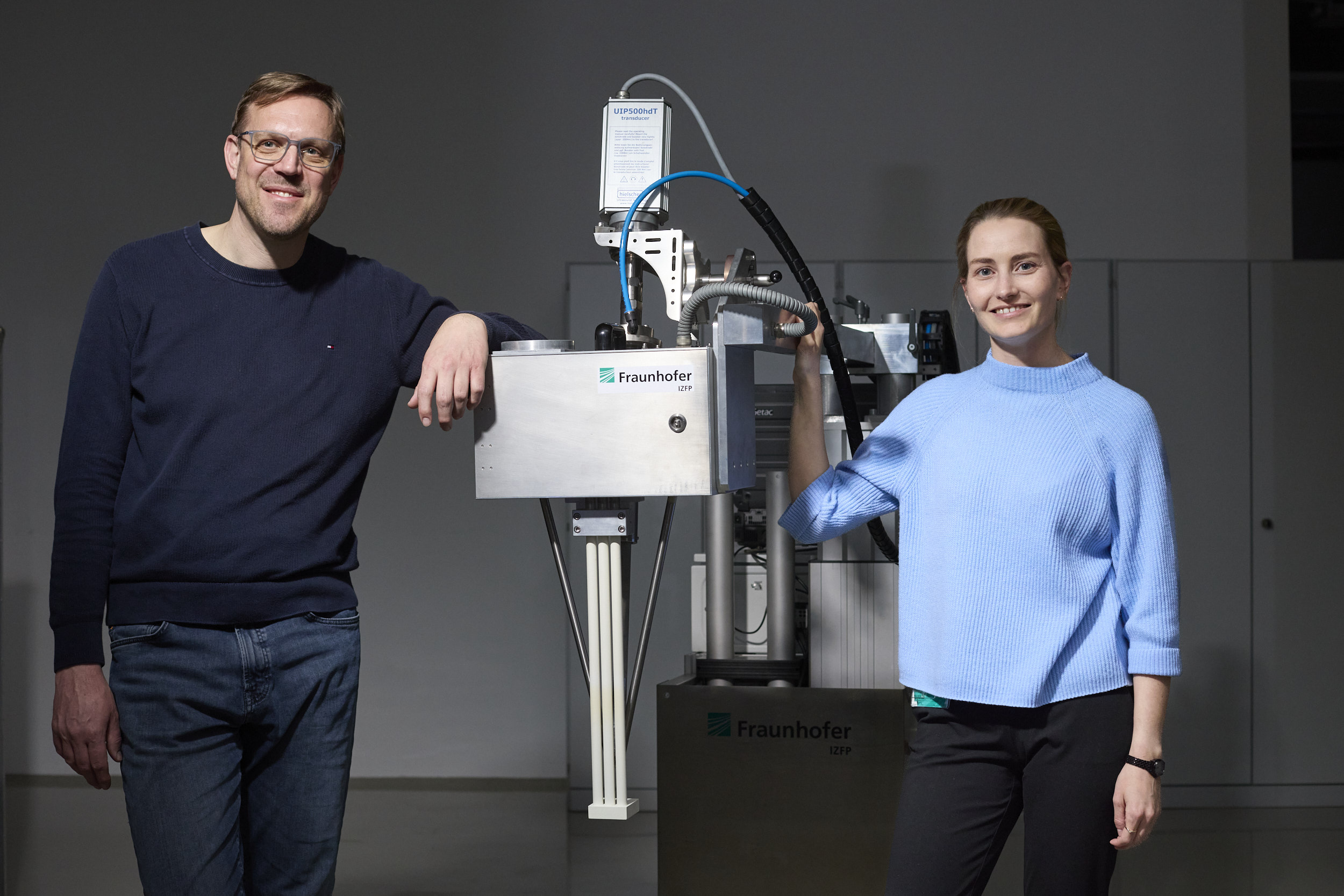

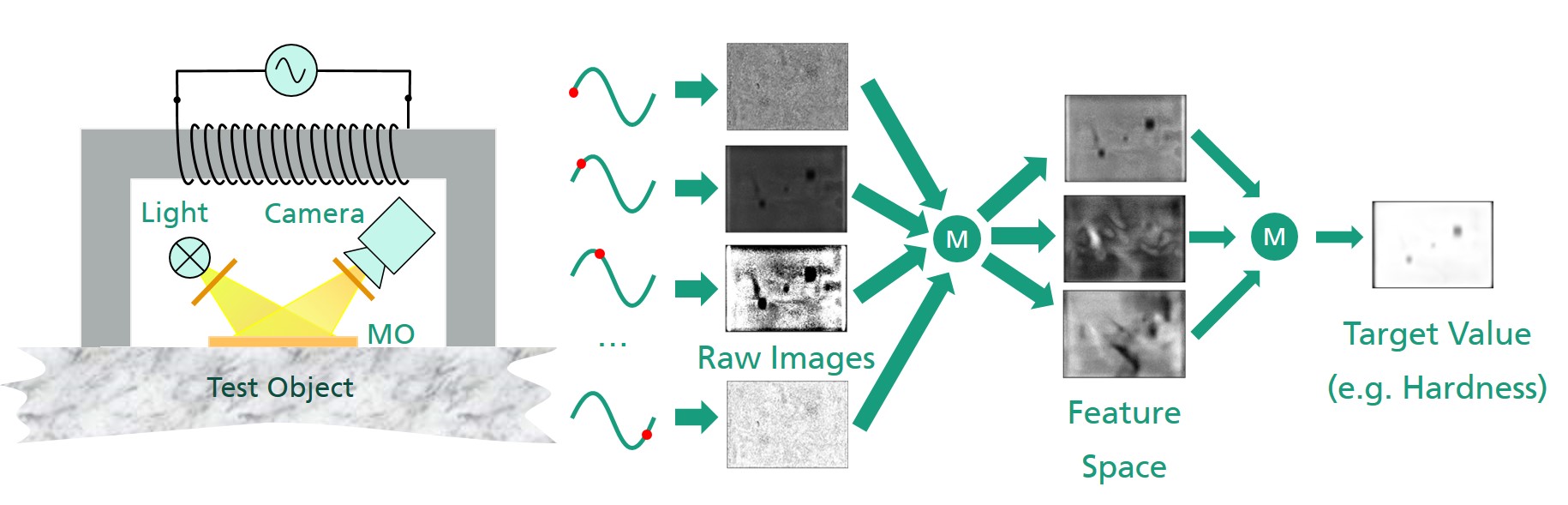

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP