Industrial optical methods enable the detection of multiple material properties, surface structures and volume characteristics in a fast and nondestructive manner. Methods such as laser-based technologies or so-called "Speckle" interferometry - which are part of Fraunhofer IZFP's core competences in optical R&D work - even allow for contactless measurements.

Optics

Tabbed contents

Application Examples

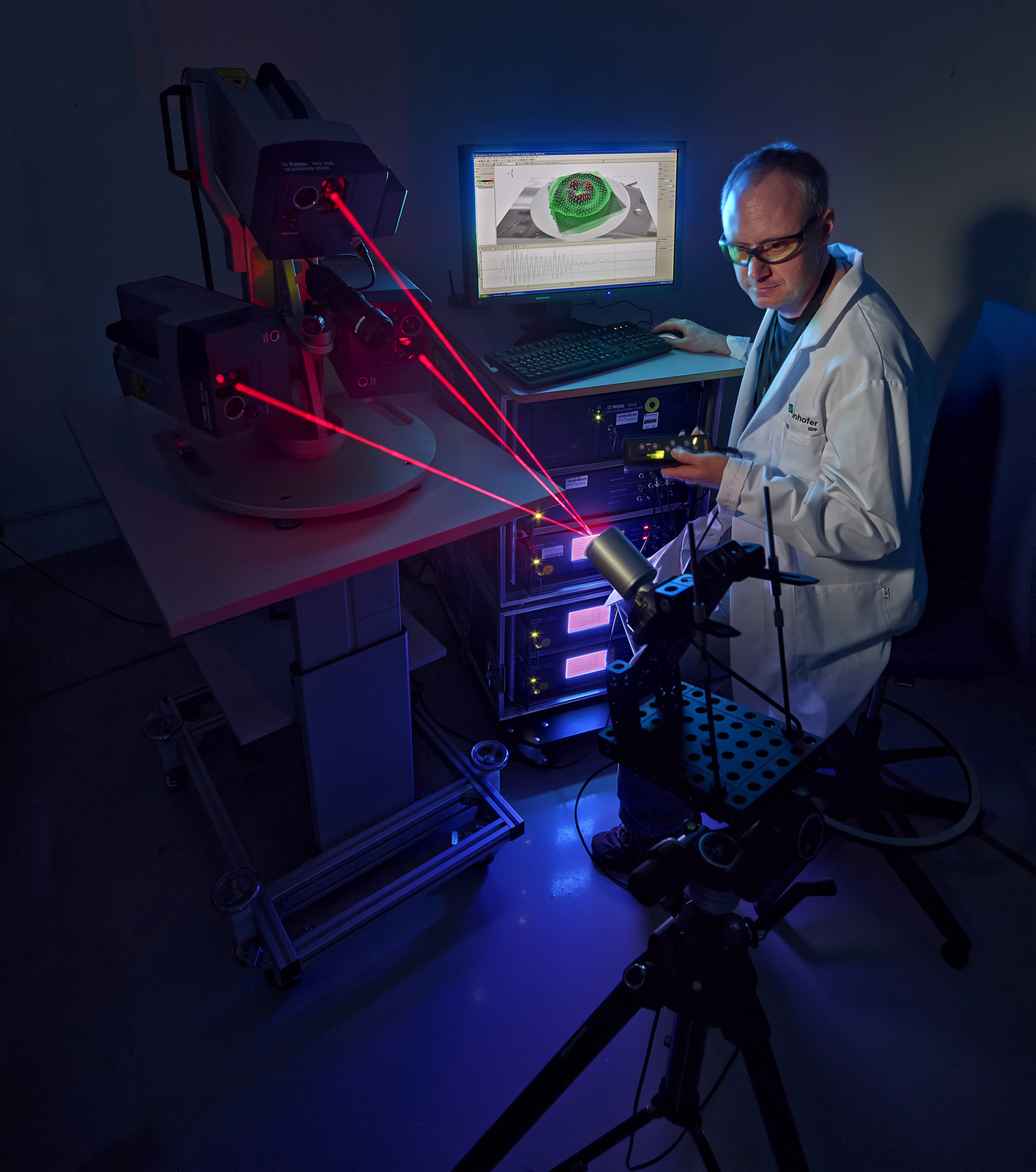

Laser Vibrometry: Three-Dimensional Noncontact Measurement and Visualization of High-Frequency Component Vibrations

Laser vibrometers enable contactless and reactionless vibration measurement and visualization. They are mainly suitable for analyzing vibration processes where conventional procedures reach their limits. Laser vibrometers make use of the Doppler effect, analyzing the specific frequency shift of a coherent laser beam impinging onto a vibrating object and being reflected from there.

Fraunhofer IZFP‘s laser vibrometer allows one-dimensional and three-dimensional measurements of vibrations. In one-dimensional mode the measurement is performed by a single measuring head which captures the vibration components running along the length of the impinging measuring beam, i.e., perpendicular to the measuring plane.

Shearography: A nondestructive method to detect hidden defects in components

Shearography, a nondestructive optical measuring method on basis of the speckle interferometry, is sensitive for local surface strain caused by defects in the volume of the component as a result of load changes. This sensitivity enables the detection of defects or anomalies within components or inspection objects. Load changes can be caused by changes in temperature or pressure or by vibrations.

Application fields

In general:

Detection of material defects:

Delaminations, Kissing bonds, Dis bonds, impact defects, drapery, etc.

Material classes:

GFRP, CFRP, Honey Comb, GLARE, foams, laminates, composites, etc.

Application areas:

Aerospace, automotive industry, wind energy, etc.

Examples:

Quality control for high-performance composites

Automated shearography system for helicopter rotor blades

NDT for glued (oder bonded) sandwich structures:

Inspection of rotor blades (wind power plants)

Tyre inspection

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP