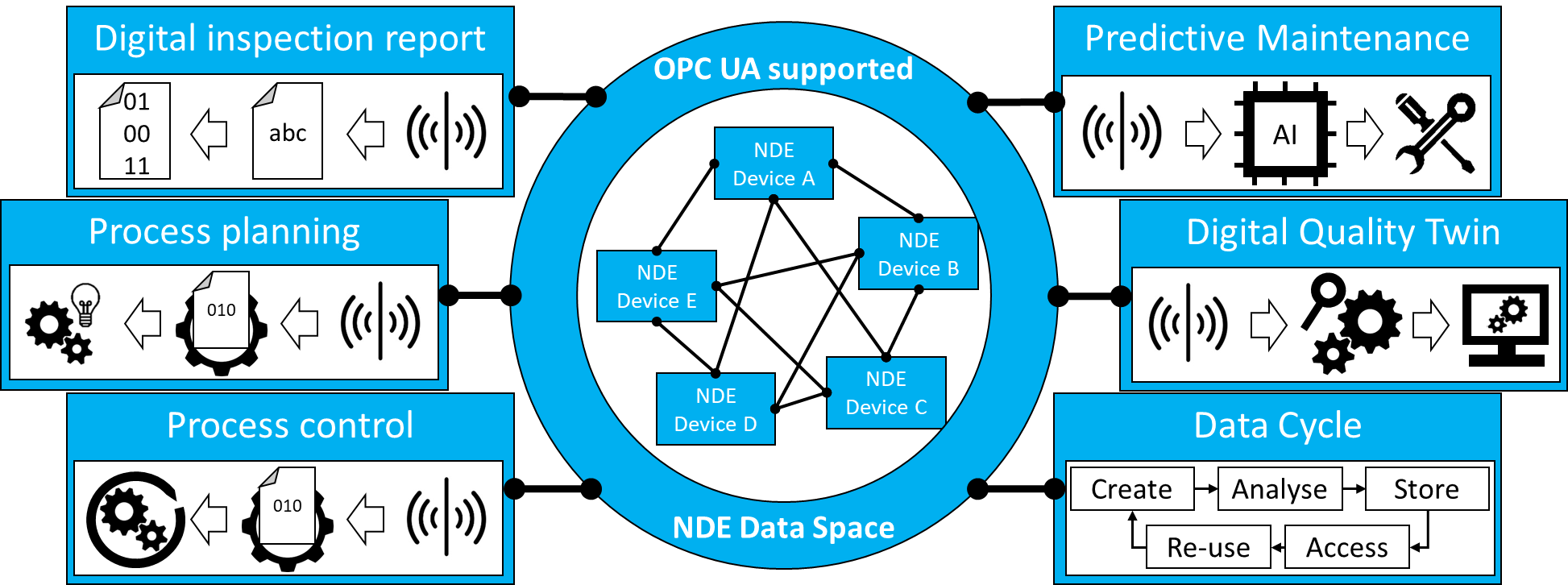

Core targets of Industry 4.0 are centered on networking and the exchange of relevant data between different subsystems at all levels of the communication pyramid. For the field of NDE, the research focus of the last decade has been primarily on the development of new methods and the unambiguous interpretation of data. Topics such as connectivity, user-friendliness and digitalization have been neglected. Connectivity in particular plays a crucial role, as it necessary for interaction with external systems and thus makes it possible to influence industrial processes in the first place. Furthermore, the requirements for data volume have increased significantly compared to the third industrial revolution. While the main requirement was still to transmit results and simple commands, the implementation of an Industrial Internet of Things (IIoT) requires a comprehensive description of all parameters, settings, functionalities, and other meta data. One potential technology that can meet these requirements is OPC UA (Open Platform Communications Unified Architecture).

As a platform-independent, service-oriented architecture for data exchange, OPC UA is characterized by the semantic description of the data. This means that the interpretation of the data in terms of its format and arrangement is not in the hands of the receiver, as is the case with the transmission of structureless packets. The system that manages the data thus specifies its structure. Through Companion Specifications (CS), such semantic descriptions are also used to map similar machines in the network in a quasi-standardized manner.

In this way, the complex information of an inspection procedure can be transmitted unambiguously, but also the complexity of an inspection job can be sent to a system. Defined in a CS, this semantic description could also be applied or at least adapted to different inspection procedures.

Fraunhofer IZFP is currently working on a CS for NDT as part of a working group of the German Society for Non-Destructive Testing (DGZfP). This Companion Specification is intended to be suitable for a wide range of test methods and address both classic manual testing and fully automated test stations.

Benefit from our expertise:

- Integration of OPC UA into your products

- Individual adaptation of information models per use case

- Support in the implementation of your systems

- Testing the connectivity of your products in our test labs

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP