The nondestructive detection of load and residual stress states in components requires an understanding of mechanical material properties and the nondestructive methods, namely ultrasonic and magnetic testing methods, which are directly influenced by these states of the workpiece. These properties are determined at the Fraunhofer IZFP in laboratory tests and, together with experiments and simulations, are further developed into methods that enable stress analysis to be carried out in the installed state or within production lines.

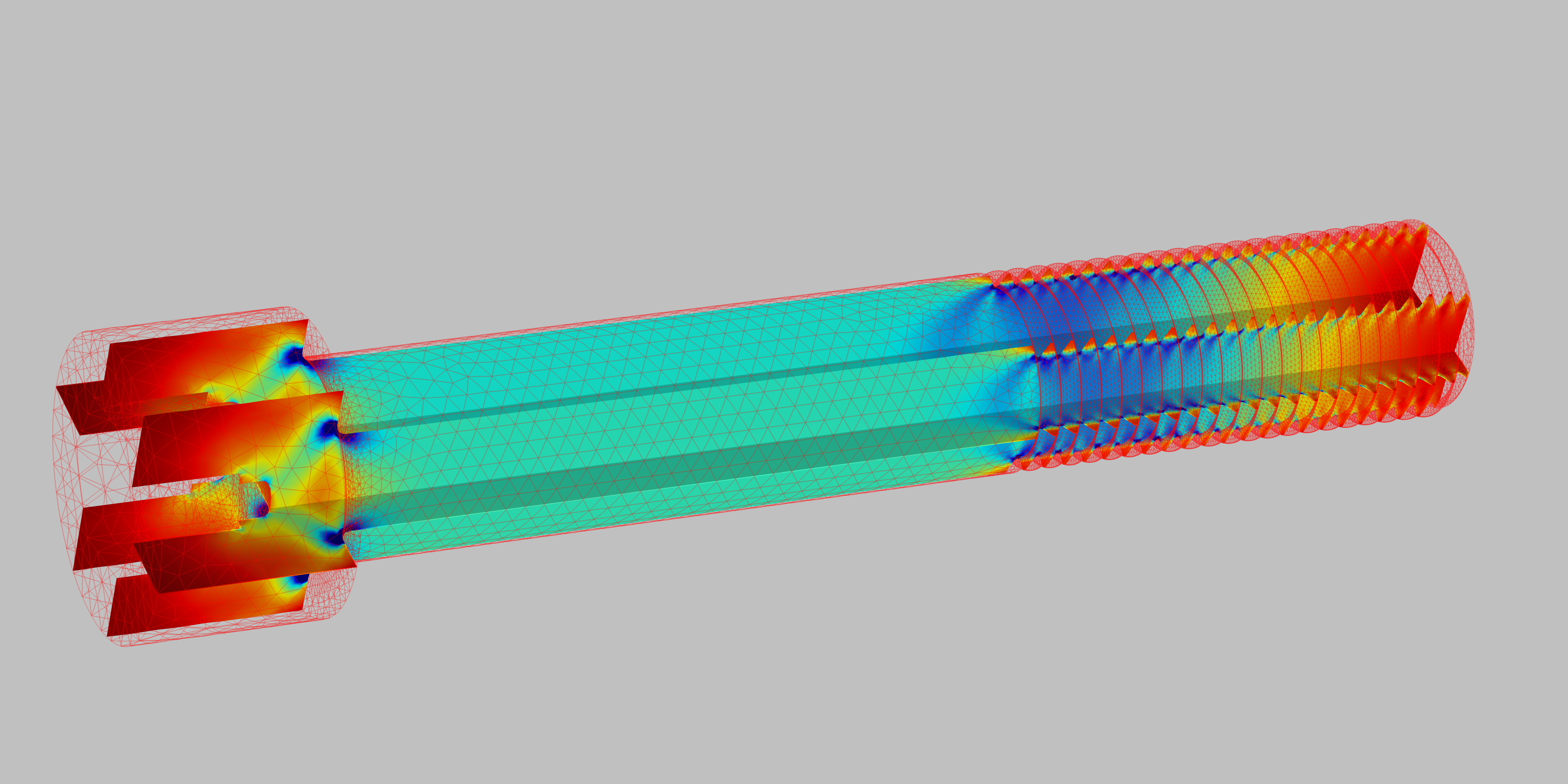

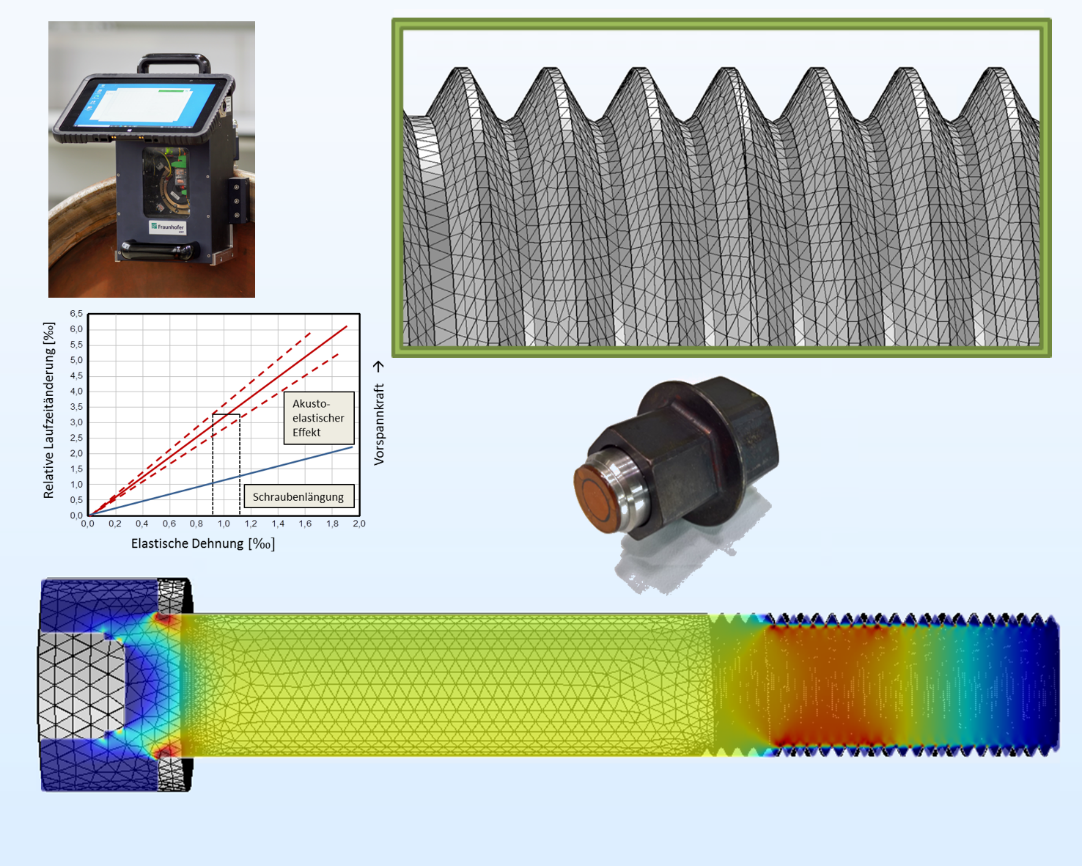

Typically, ultrasonic methods utilizing the acousto-elastic effect enable statements to be made about the absolute prevailing stresses. The ultrasonic transit time measurements required for this are carried out using high-precision methods, which often have to be reproducible to within one or two nanoseconds.

As a relative test method for stress determination, magnetic stress determination relies on comparable samples in comparable states. If these references are available, the remagnetization behaviour of the material can be used to perform a robust stress determination, which is often less susceptible to operating errors than a comparable ultrasonic measurement.

Robust signal generation, reliable test devices and experimental evaluation methods are often essential for the implementation of previously unsolved voltage measurement problems, especially for complex components and difficult test environments. Understanding and being able to adapt this entire chain is our aim in all research and development topics.

Which stress determinations have been covered so far?

- Preload force of screws

- Thermal residual stresses of railroad wheels

- Load stresses in railroad tracks

- Residual stresses in sheet metal

What types of projects can be carried out in this area?

- Development of new testing methods for ultrasound

- Development of improved evaluation methods for ultrasound and magnetics

- Research into new testing strategies for new types of components or materials

- Studies on the reproducibility and feasibility of stress measurement methods

- Studies on the absolute accuracy of the methods used, taking into account fluctuations within defined material groups and existing error influences

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP