Holistic materials characterization of plastics and fiber composites: three Fraunhofer institutes are bundling their competences

Press Release / March 2, 2018:

Collaborating and networking - this is the contemporary response to the technological and scientific challenges of our times, which are becoming ever more complex. This is the reason why the Fraunhofer Institutes for Nondestructive Testing IZFP, for Mechanics of Materials IWM, and for Structural Durability and System Reliability LBF are now bundling their competences. It will allow them to provide a comprehensive portfolio for holistic material characterization of plastics and fiber composites for component design. The collaboration comprises both the scientific approach and the industrial application of the solutions found. The advantage of such networking: clients will be provided with a combined, validated concept for their design and measuring methods instead of getting individual components. In their new collaboration, the three institutes will welcome cooperation with partners with whom they can work on challenging scientific issues in joint projects.

The bundled competences of the IWM, IZFP, and LBF Fraunhofer Institutes comprise applying on-site methods for analyzing microscopic and macroscopic damage propagation, as well as deducing and modeling damage mechanisms in numerical material and failure models. In particular, for the genesis and propagation of cracks in plastic, very well validated methods are available that allow determining the necessary parameters. For plastics and fiber composites, there are currently no concepts and experiences with these parameters that would allow using them for the design and dimensioning of components. The advantages of dimensioning based on fracture mechanics is obvious: increased reliability and lower component weight.

Capabilities at three sites

The Fraunhofer IWM works in the area of mechanism-oriented material characterization and modeling. By means of micro-sample testing methods accompanied by numerical simulations, the genesis of cracks can be observed at the microscopic level and made accessible to numerical simulation. Based on the results of these examinations, the Fraunhofer IWM develops macroscopic material models, and implements user-defined modules in commercially available finite-element applications, making them available for calculating components.

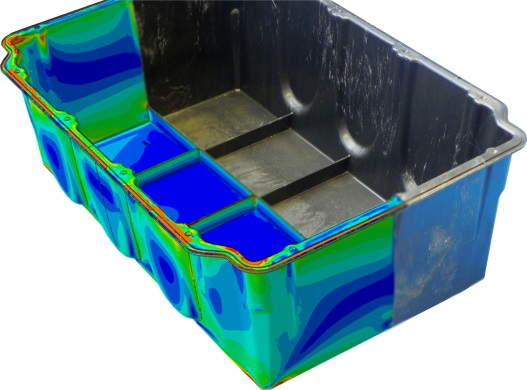

The research of the Fraunhofer IZFP focuses on the area of nondestructive characterization of plastics and fiber composites. High-resolution computer tomography as a reference method allows analyzing the mechanisms of how defects arise as well as the characteristics of materials at the micro-structure level. In addition, ultrasound, thermography and multi-frequency eddy current methods and their associated testing processes for characterizing damage development due to defects in plastics and fiber composite materials represent a key focus of the research and development activities of the Fraunhofer IZFP. Its work covers the entire value-added chain of the product lifecycle ranging from material and component development to production monitoring to operations.

The Fraunhofer LBF characterizes plastics and fiber composites with regard to their vibration characteristics under real-life application conditions. The resulting parameters are integrated into a concept for durability-focused dimensioning of structural components made of plastics and fiber composites. Macroscopic and thermographic methods allow determining the crack initiation and propagation behaviors as well as the hysteretic heating under a vibration load. The results can be used to determine interactions between mechanical loads and environmental factors on the one hand, and strength on the other so that they can be taken into account when designing components.

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP