Fraunhofer IZFP @ CONTROL 2023: Intelligent assistance system “3D-SmartInspect“ with interactive visualization for laboratory and service tasks

Saarbrücken, April 25, 2023

A planned service life of structures can only be achieved if the quality-assured execution of construction measures and the necessary maintenance measures during the service life phase are coordinated. This is why, it is usually necessary to record component-specific characteristic values nondestructively and with high accuracy of the measured value recording and localization. How this works will be presented by experts of the Fraunhofer IZFP from May 9 to 12, 2023 at the 35th Control in Stuttgart (Hall 7, Booth 7301) with “3D-SmartInspect“, the intelligent assistance system for digitizing manual inspection.

In manual testing, the quality of the test depends heavily on the personnel and the environmental conditions. Both, the correct analysis of the measured values and the complete coverage of the test area require a high level of expertise. In addition, there are considerable challenges for companies with regard to test execution: Up to now, test protocols have been written by hand and detected anomalies have been marked on the components themselves. In general, there is no digital connection between the test object and the test performance.

Interactive inspection and digital documentation

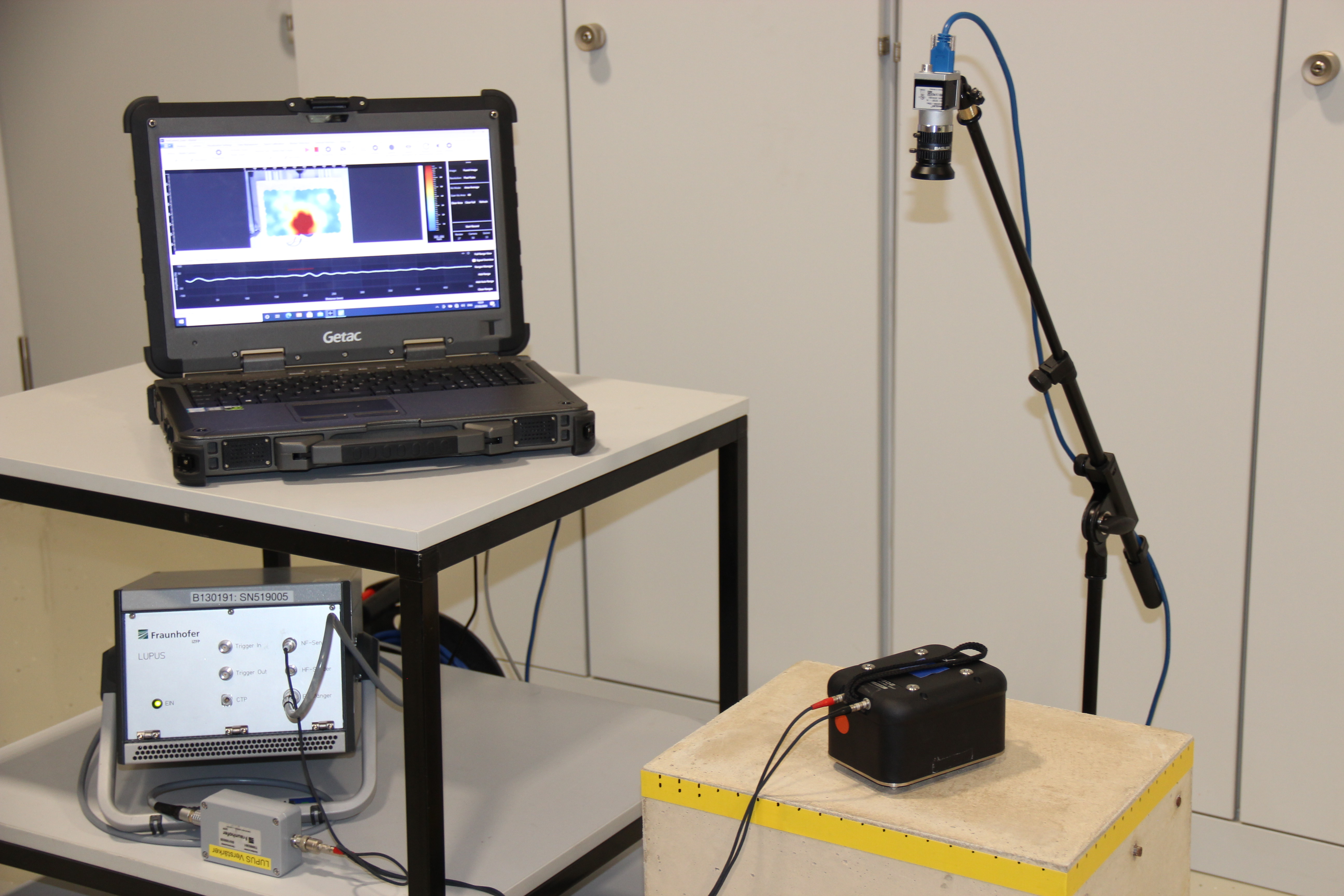

3D-SmartInspect is a system with interactive and intelligent assistance as well as digital documentation for manual inspection. The inspection process is captured optically; a tracking module traces the movement of the probe and logs inspection positions and measurement signals. The recorded measurement signals and volume data are evaluated with AI support and fused with location coordinates for the live image. An augmented reality module also enables visualization with “HoloLens“ glasses. For use in Industry 4.0 contexts, the result is finally transferred to DICONDE (Digital Imaging and Communication for Non-Destructive Evaluation) in the form of a digital component file. This allows the recorded data to be compared and analyzed with other NDT methods.

Significant relief and assurance of quality

3D-SmartInspect can be used in all application areas of manual inspection, e.g. in construction, aerospace (safety-relevant components), energy systems (turbines, generators, high-pressure vessels, etc.) and large-scale equipment construction. The assistance system ensures a 100 % inspection with the inspection time reduced through interactive visualization. The fusion of location data and measurement data allows to calculate and quickly display reconstructed data on-site. In addition, 3D-SmartInspect with its automatic documentation of the test results has a digital test memory available. The digital component file created by the system implies a considerable relief for inspectors.

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP