Mobile manual inspection system for wheelsets with full storage of inspection data

Mobile, complete manual inspection of railway wheelsets including full storage of all inspection data for long-term traceability

Material inspection of railway wheelsets is an integral part of safe rail transportation. Today, ultrasonic inspection of rail wheelsets is carried out stationary in large workshops using the AURA system, which has been in use since 1999. In smaller workshops, this inspection is usually carried out manually. In the latter case, storage and thus possible traceability of the inspection results is next to impossible due to the volatility of the data.

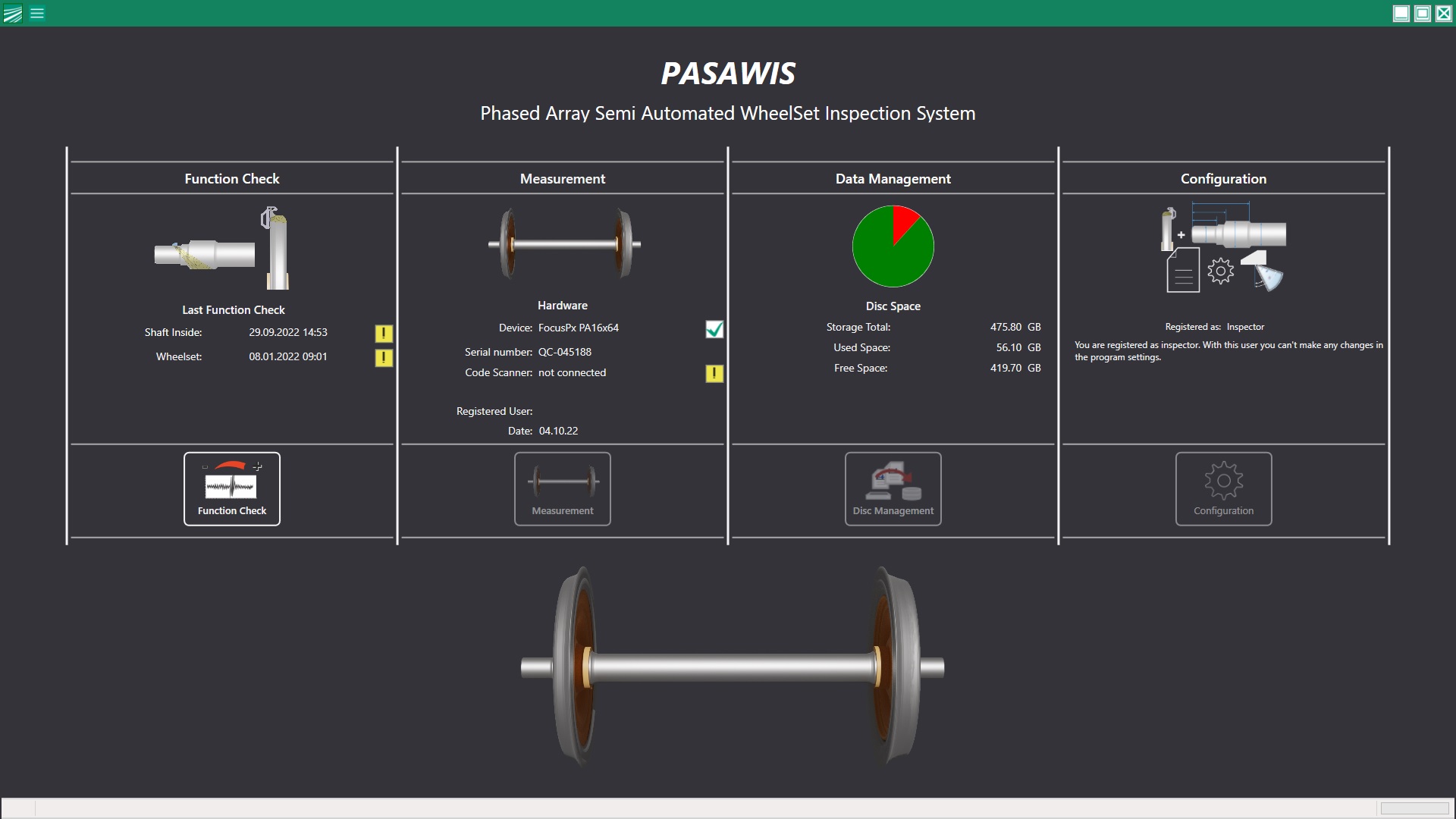

The “PASAWIS“ inspection system (Phased Array Semi-Automated Wheelset Inspection System) is a joint development of Fraunhofer IZFP and Evident GmbH in collaboration with Railmaint GmbH, providing wheelset inspection of the next generation. In this context, it fulfills the requirements of VPI European Rail Service GmbH (VERS) according to VPI-EMG 09 for the maintenance of freight cars by means of non-destructive testing.

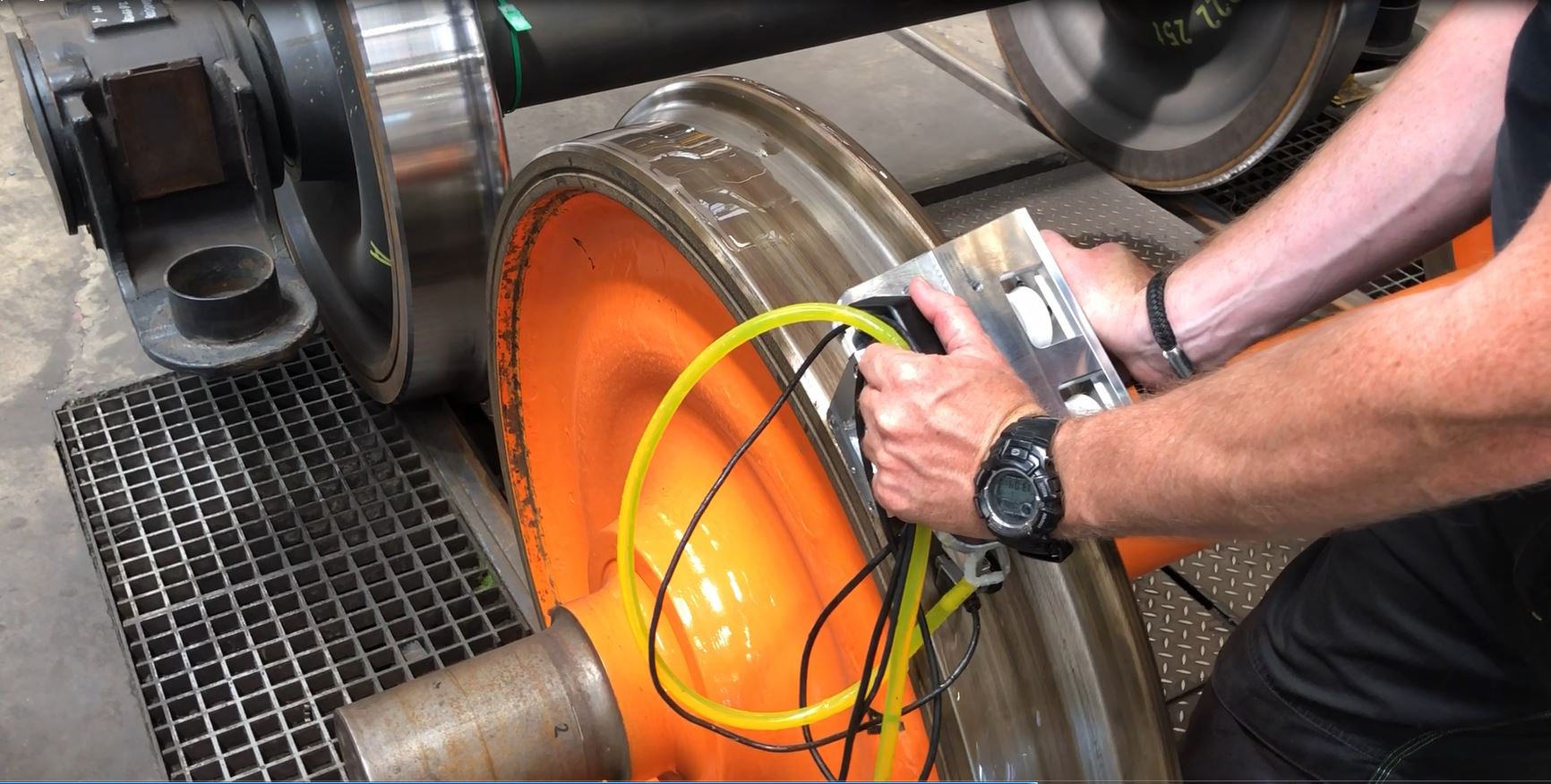

Using three hand-held scanners and pre-defined inspection programs, “PASAWIS“ enables a complete wheelset inspection including shaft, rim and tread. The mobile system can be deployed in production and operated by one person. It consists of an ultrasonic unit (phased array) with customized software.

With “PASAWIS“, for the first time the full storage of test data sampled by manual inspection is possible, with the consequence of long-term traceability and reproducibility. The locally stored data can be transferred to central storage locations via multiple interfaces. Also possible is a straightforward upload to cloud-based document management systems.

Inspection parameters such as inspector, inspection date, signal amplification or inspection areas are documented in DICONDE format (Digital Imaging and Communication for Nondestructive Evaluation) according to ASTM E2633 14 US. This open standard with attached PACS (Picture Archiving and Communication System) meets the highest requirements and allows images and digital data from industrial materials inspection to be displayed, transmitted and stored.

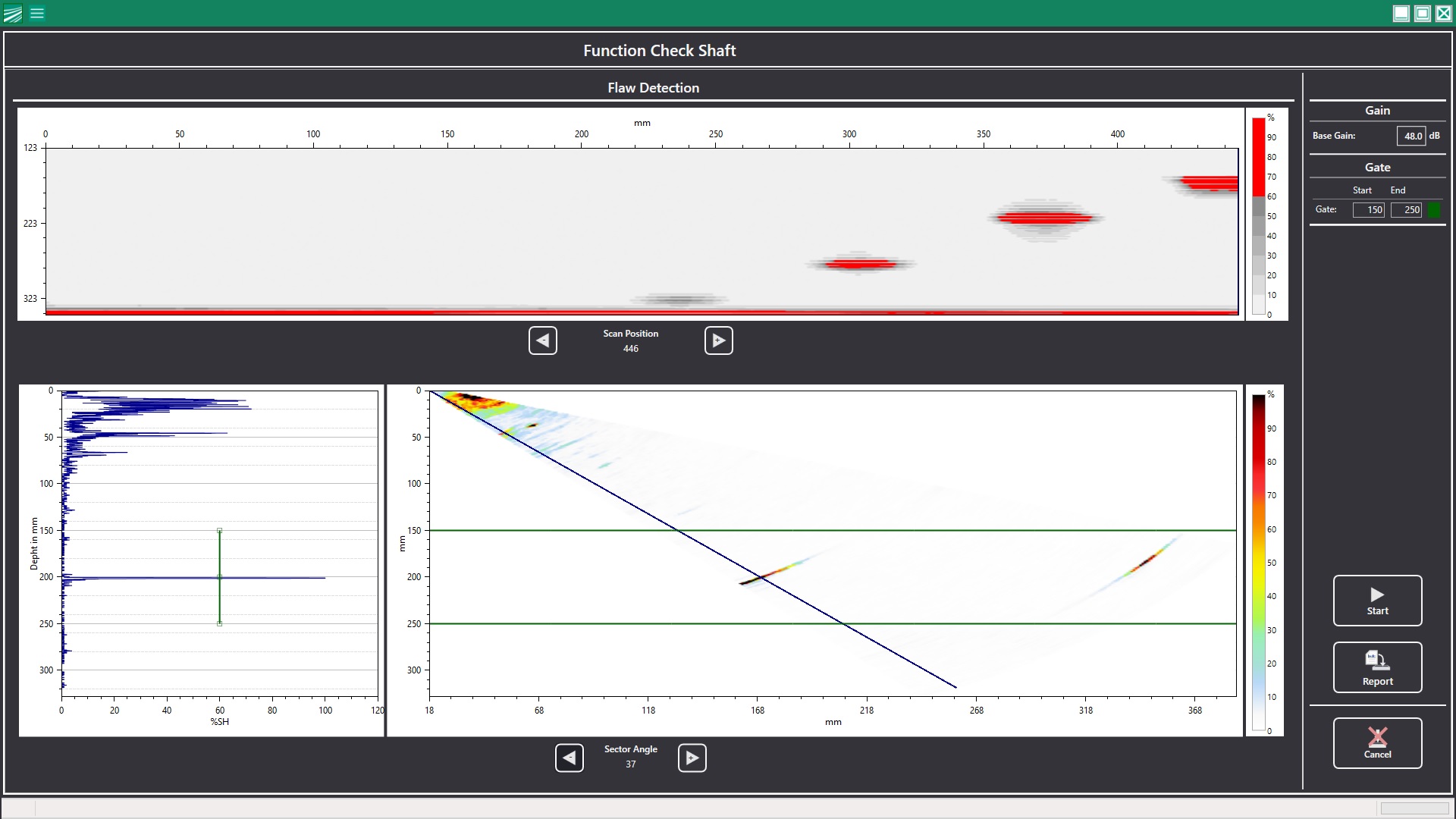

Inspection results are automatically stored as PDF files in customized inspection reports containing the graphical results associated with the individual wheel set, such as A-scan, sector image and C-scan, as well as further associated data, such as calibration date, instrument serial number, name of the inspector and workshop. Minimal manual input is required for report generation. The test report is provided with a safe digital signature, ensuring a significantly increased level of security.

Advantages:

- meets the requirements of VPI-EMG 09

- automated inspection reports

- digital signature

- full wheelset inspection

- mobile use in production

- short inspection times

- individually configurable

- automatic transfer correction

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP