Uprightly anchored poles carrying lamps, traffic lights, or traffic signs are affected by corrosion due to environmental stress factors such as soil moisture, humidity inside the pipe, air pollution, or dog urine. The emerging attenuation of the pole wand thickness has the potential to harm the structural safety of the poles.

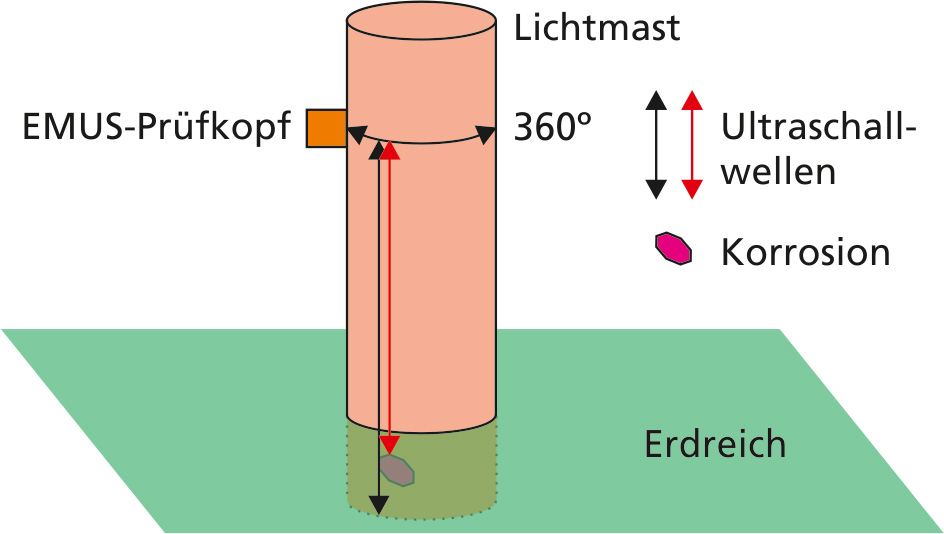

The area critical for corrosion damage is located immediately above and below the soil level. The remaining residual wall thickness is a relevant parameter for the assessment of the structural stability and the bending strength of the affected pole. However, conventional piezo-electrical ultrasound inspection allows but inspecting only the above-ground part of the pole, while critical corrosion areas below the soil level remain hidden.

The underlying inspection technology exploits the capability of guided ultrasound waves for spreading over long distances and for detecting corrosion-induced wall abrasion. An electromagnetical probe (EMAT) generates a horizontally polarized, guided wave that spreads longitudinally within the pipe wall. In case of corrosive wall abrasion part of the ultrasound energy will be reflected back to the probe and registered as an echo signal. The choice of the deployed ultrasound modes and the chosen frequency range effectuate the reduction of signal attenuation by anticorrosive coating, soil and concrete to a degree that even hidden and inaccessible areas can be inspected.

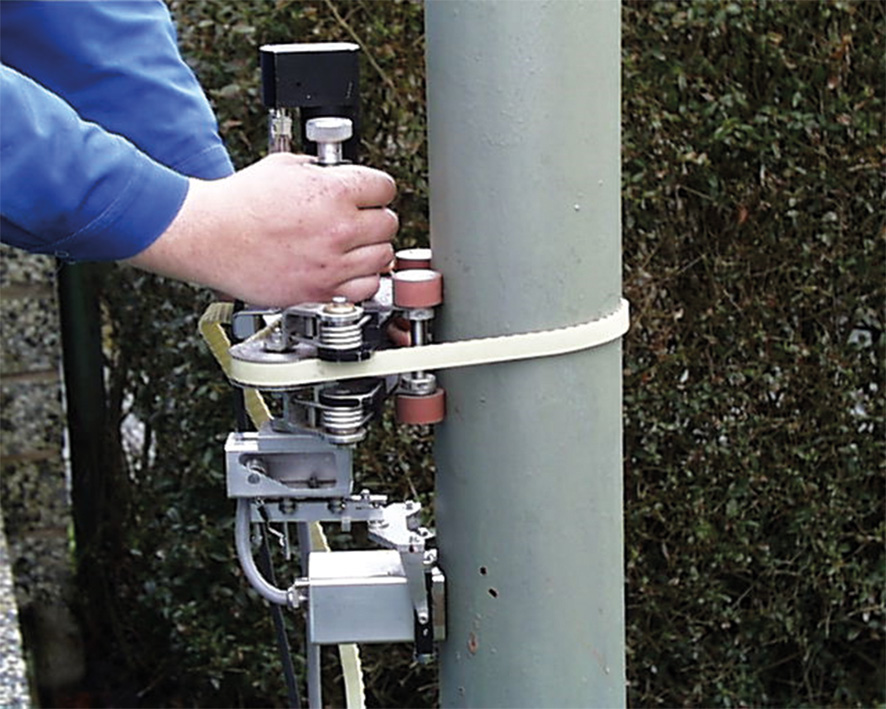

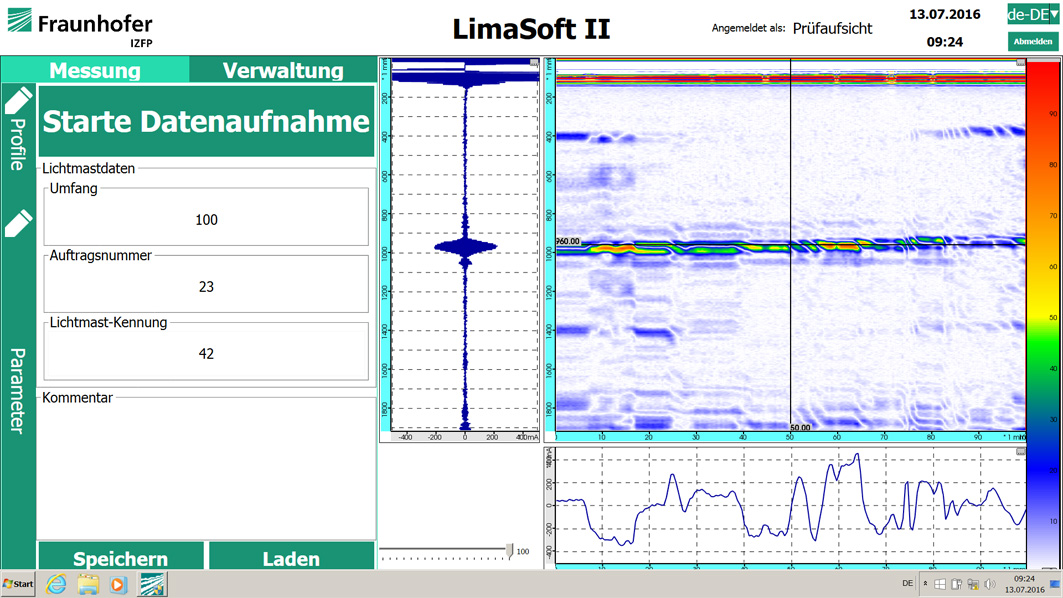

The use of electromagnetical ultrasound probes enables dry measurements without need for any couplants. Moreover, there is no need for special preparation of the pole surface such as removing color or rust layers. While the probe is moved around the outer sheath of the pole manually or by manipulator, the software captures the echo signals and visualizes them as a so-called ultrasonic B-scan. Only minutes from the start of the inspection, reliable information on the corrosion condition of the pole are available for assessment and archiving.

LIMAtest® inspection system was developed in cooperation with ZWP Anlagenrevision GmbH.

Application

- Fast and and complete exterior inspection of light poles for corrosion in areas inaccessible from the outside

Features

- Compact inspection system with EMAT reveiver/transmitter electronics

- Fast data pre-processing

- Laptop for device control, data recording and visualization

- Automated archiving of measured data and generating of inspection sheets

- Integrated user and inspection profile management

- Optional: manipulator für motorized 360° scans of light masts

- Expandable modular language options

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP