Process-integrated in-line quality assurance of joints for lightweight construction in the automotive industry (PROFILE)

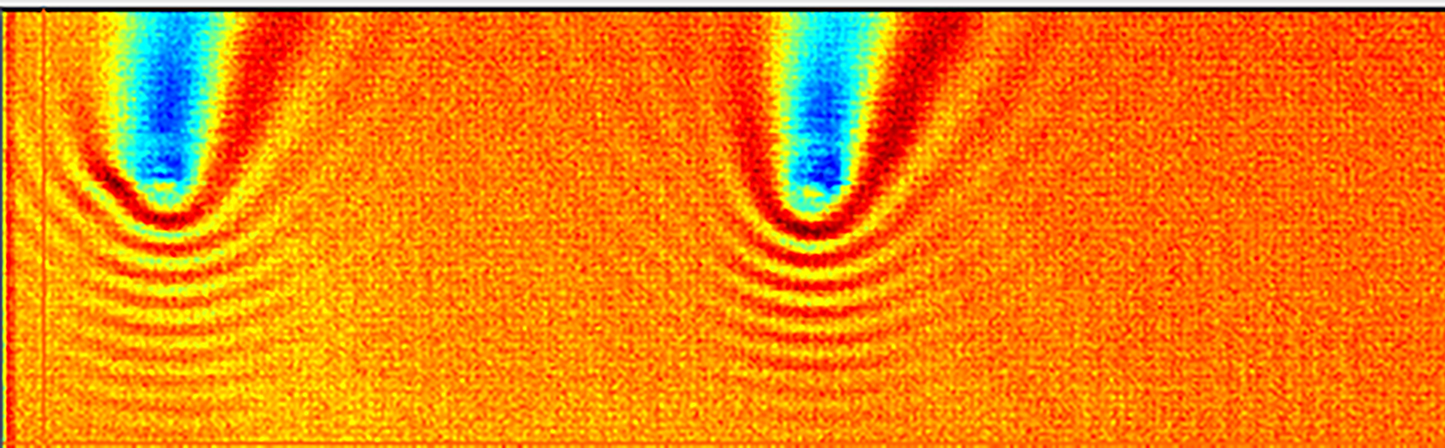

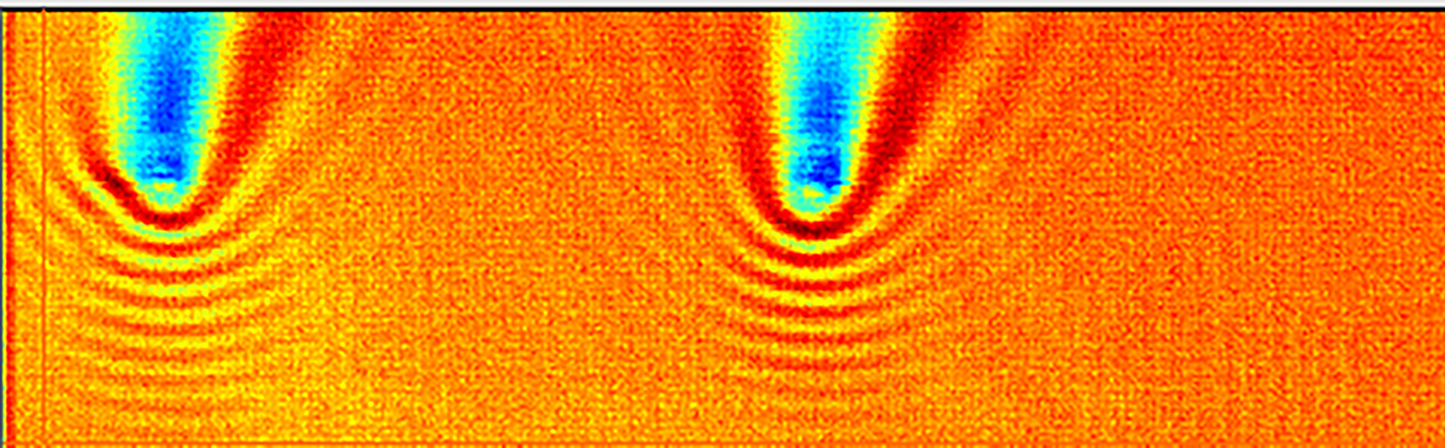

Non-destructive ultrasonic testing methods are an important tool for material testing/quality assurance due to their traceability to elastic or mechanical properties. In many cases, air-coupled ultrasonic methods also offer simplified and reproducible coupling conditions for the ultrasound and thus allow a safer and simplified application of the method.

As part of a cooperation project funded by the ERDF (European Regional Development Fund), this process is being further improved by Inoson GmbH as an industrial partner together with the Fraunhofer IZFP through a largely physical decoupling of the transmitter and receiver of an ultrasonic system (piezoelectric excitation / optical evaluation).

The aim is to achieve higher error contrasts in addition to a simplified test procedure application. This is achieved by identifying and using special sound propagation modes. A further aim of the project, in addition to process development, is to set up a pilot plant for demonstrating and, in particular, experimentally evaluating the process. Inoson GmbH realizes the project.

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP