Although the last nuclear power plants in Germany have been shut down, it remains important for Germany to be able to assess the condition of nuclear facilities and evaluate material behavior in view of their operation and the associated extension of their operating life to 60 years in neighboring European countries. This applies to all components of nuclear power plants, regardless of the material used. In addition to the reactor pressure vessel and the cooling water pipes, this applies in particular to the cables installed, which are required, among other things, to maintain the energy supply and operate the sensors.

The “PolySafe” project series, funded by the German Federal Ministry for the Environment, Nature Conservation, Nuclear Safety, and Consumer Protection (BMUV), is looking at the aging of cable insulation, with a particular focus on the combination of EPR and CSPE polymers used in nuclear power plants. PolySafe thus sheds light on a previously little-considered but highly relevant topic—the determination and evaluation of operational changes in cable insulation during long-term operation and under accident conditions.

Task/implementation

The aim of the “PolySafe 2” project phase, which started at the end of 2023, is to develop a practical test concept for cables in nuclear facilities. This development is based on the technological and methodological approaches of the first project phase, PolySafe 1, in which laboratory setups for ultrasonic (US) and terahertz (THz) testing as well as data processing concepts were already developed. In the current project phase, these concepts are being adapted so that they can be used under practical conditions. In addition, the current project phase involves the use of a loss factor measurement method which, in contrast to US and THz technology, also detects externally inaccessible points along a cable route and thus characterizes them integrally. The project is looking at twelve different states of aging with the aim of achieving the finest possible gradation of the aging states, as this is a prerequisite for the development of a differentiated method for estimating the remaining service life. Aging is achieved thermally. In addition, following aging, a test is carried out under LOCA (loss of coolant accident) conditions to simulate an accident, as this is a prerequisite for the approval of a cable within a nuclear power plant.

Results

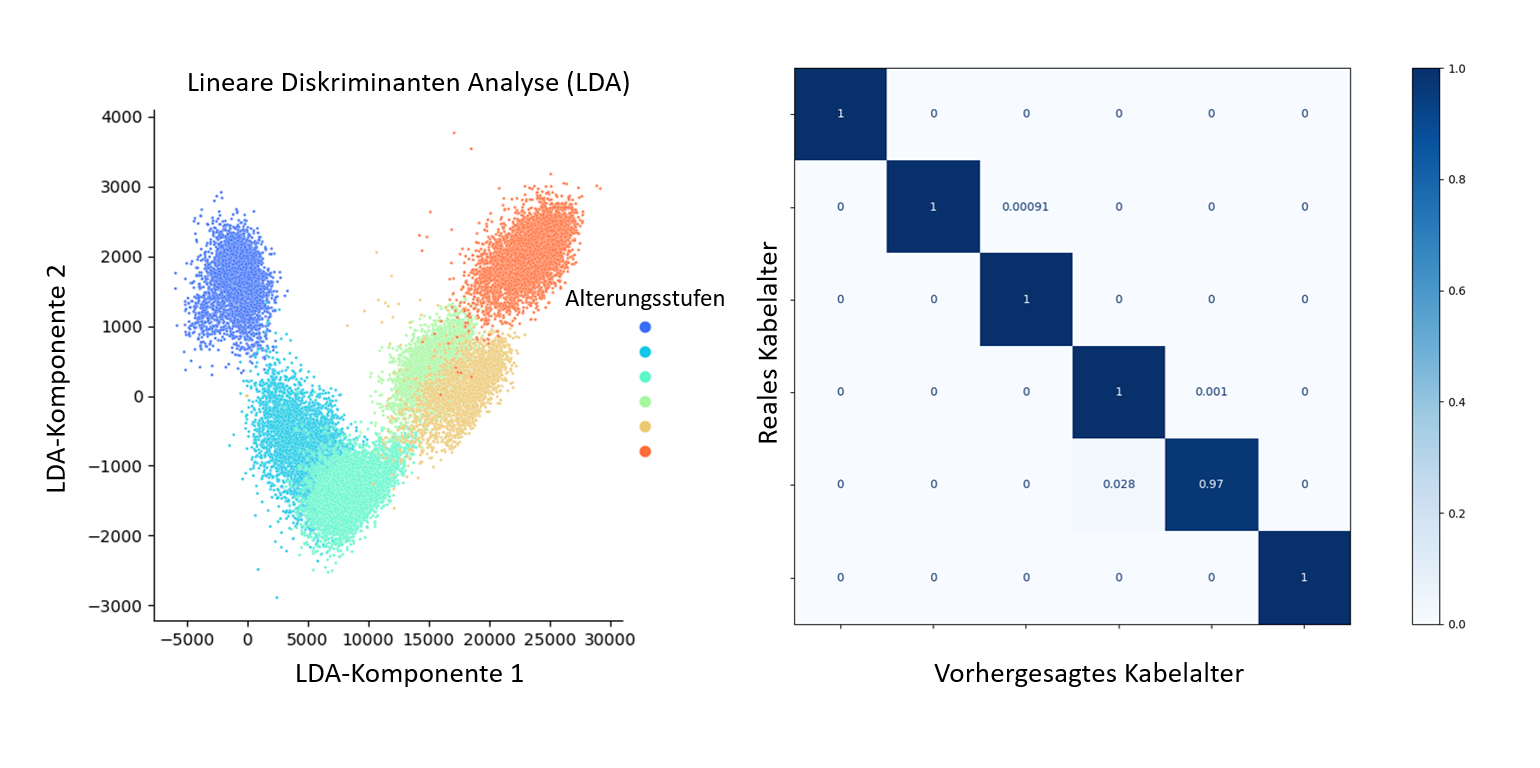

In PolySafe 1, US and THz measurements were performed on EPR and CSPE cable insulation in different states of aging. The data obtained was correlated with results from tensile tests (including elongation at break – EaB) using machine learning algorithms (e.g., LDA). The EaB value serves as a reference here, as there is a direct correlation between age and a reduction in EaB. It was demonstrated that the two methods used enable a fundamental distinction to be made between the states of aging.

Advantages

Nondestructive determination of the remaining service life of cables in operation has several advantages over testing samples stored in the nuclear power plant. The latter are limited in number and may not be available in sufficient quantities as the service life is extended. In addition, cables are subject to different loads due to their different locations in the nuclear power plant, meaning that they do not age uniformly. Individual cable evaluation during operation enables local observation of conditions and thus early detection of deviations in aging behavior, which in turn allows better control of component replacement, for example.

PolySafe 2 is being developed jointly with the Society for Plant and Reactor Safety (GRS) non-profit limited liability company and the German Federal Ministry for the Environment, Nature Conservation, Nuclear Safety, and Consumer Protection (BMUV).

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP