K3I-Cycling is the short title of the project ”AI-supported optimization of the recycling of plastic packaging”.

Packaging accounts for the by far largest share of plastic waste worldwide. Due to major technical and economic challenges in sorting the recyclable materials – challenges that often prove to be too great – often only a small part of the plastic re-enters the cycle as a secondary raw material. For example, the sensor technology currently used in sorting often results in false discards, where , for example, recyclable PET bottles end up in the fraction for thermal processing leading to a loss of recyclable material. Sorting these false discards by hand is possible, but not economical and is therefore often not carried out.

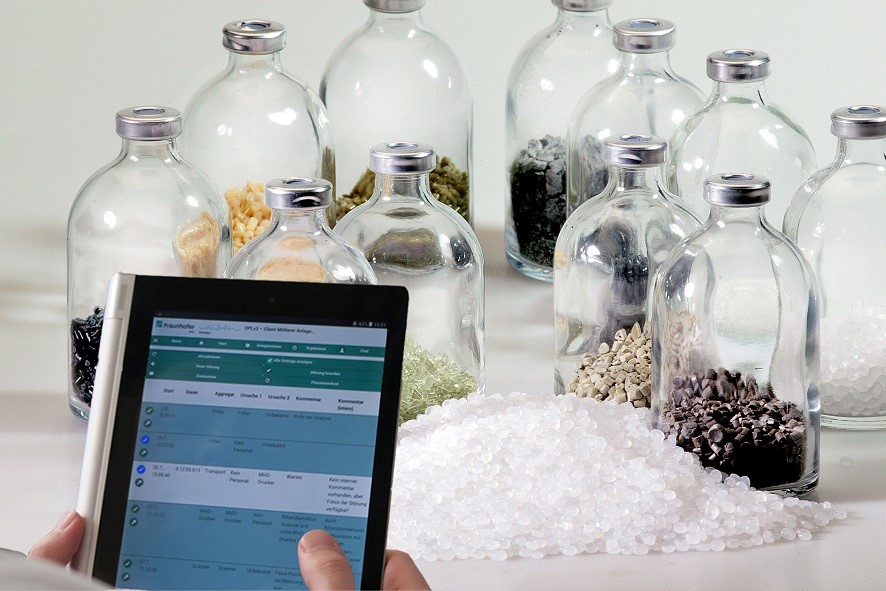

K3I-Cycling focuses on the significant quantitative and qualitative improvement of material recycling of post-consumer plastic packaging waste. To this end, K3I-Cycling is using an ”Artificial Neural Twin” to develop a new, open and standardizable AI interface for the cross-sector collection of relevant information in the sense of a light packaging product passport. This, for the first time, enables digital networking of all stakeholders along the value chain. An ”Artificial Neural Twin” is a fully differentiable representation of the entire system, allowing individual components to be optimized in relation to the entire system. In this process, sensory information of all kinds along the material flow is captured as data.

In a hub, 51 partners from business, science and society collaborate in two innovation labs: KIOpti-Pack for design and production and K3I-Cycling for mechanical recycling. An important objective is the cross-laboratory exchange of data in order to consider findings across the entire value chain. In addition, the hub's topics around artificial intelligence and the circular economy for plastics are to be made accessible to the general public through a variety of events and communication measures. Among other things, a podcast and an Open Hub Day are planned for this purpose.

Fraunhofer IZFP is sharing its expertise in cognitive sensor and data systems, artificial intelligence, monitoring, and the recycling of materials with the K3I-Cycling innovation lab. Within this framework, an active thermographic sensor system for sorting tasks is being developed, which obtains material information from lightweight packaging plastics without contact and in real time. The raw data obtained will be processed using machine learning (ML) techniques aiming at optimized feature extraction and material classification. The same methodology is applied to data from Fraunhofer FHR using terahertz sensor technology. Furthermore, an investigation of possible synergistic effects of the thermography and terahertz data in the ML models is performed.

The consortium in K3I-Cycling comprises several Fraunhofer partner institutes, as well as diverse partners from industry, research and education.

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP