EMUS-4-Stress is the short title of the project ”Condition monitoring system based on electromagnetically excited ultrasonic transducers”.

The knowledge of the thermo-mechanical stress state of components is essential for the operation and safety of thermally and mechanically cyclically loaded nuclear facilities (e.g. thermo-mechanically loaded components in nuclear power plants). The national and also more and more the international conversion of power generation structures towards the increased use of solar and wind energy inevitably implies an increase in the standard loading share of the classic thermal power plant park, which results in an increase of stress-related fatigue load. The knowledge base for decisions on operation, maintenance and monitoring has to be improved accordingly. In the ever more important ageing management of nuclear facilities, the real time profile of the thermo-mechanical stress is of major importance. Thus, for pipe systems, the development of a method is crucial, which allows the determination of the thermo-mechanical stress state over the inner pipe wall surface.

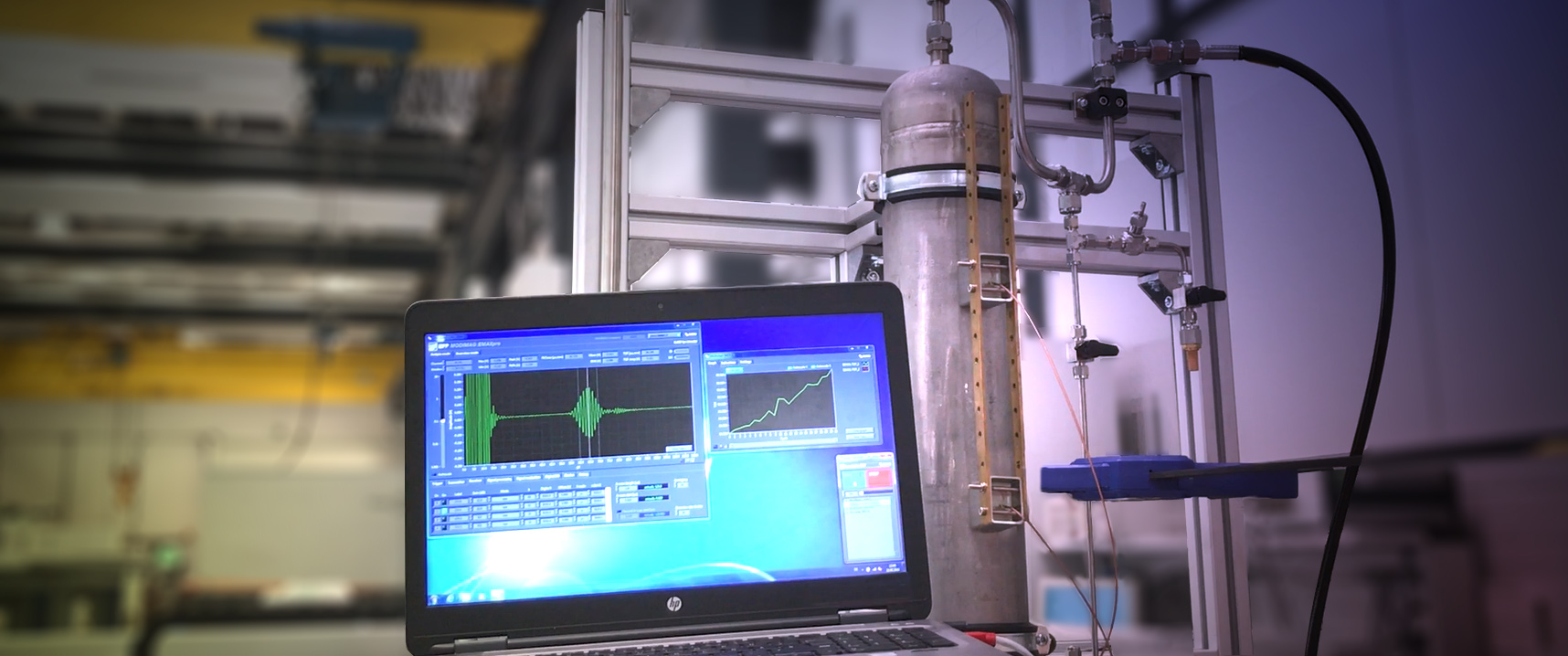

The overall objective of the BMWi-funded EMUS-4-Stress project concerns the development of a method to determine load-related stress gradients – which build up starting from the inner wall of pipelines – by measurements from the outer wall, even in the case of rapid load sequences. This enables the early damage detection and the monitoring of components in nuclear facilities. To begin with, in two feasibility phases of one year each, the principle applicability of the EMAT-based stress measurement for this purpose was demonstrated. Currently, the third phase (implementation phase) of the development project is running, which strives for the synergetic combination of and FAMOSi-based monitoring of ductwork.

In the third phase, Fraunhofer IZFP pursues two core objectives: On the one hand, FAMOSi will be extended by metrological components developed by Fraunhofer IZFP based on EMAT transducers, which detect fast stress transients at inner pipe walls notwithstanding measurements from the outer wall. On the other hand, high-frequency load changes, which are not recorded by FAMOSi, are calculated by a routine trained at Fraunhofer IZFP. This routine resorts to the ultrasonic time-of-flight data, which is by far more responsive.

The EMUS-4-Stress 3 project is realized together with TU Kaiserslautern’s Chair of Materials Science (WKK) and Framatome GmbH. It is accompanied by the Materialprüfungsanstalt (MPA) Stuttgart in a subcontract.

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP