Steadily rising standards in lightweight design require the use of novel materials such as carbon fiber reinforced plastics (CFRP). In order to apply the nondestructive material inspection to these electrically weakly conductive materials, it is mandatory to increase the inspection frequency. The inspection is influenced by two physical material characteristics, electrical conductivity, and magnetic permeability. These characteristics depend on quality parameters of the material, e.g.

- heat treatment, texture formation and texture differences (case hardness, etc.),

- mechanical properties (firmness, hardness, residual stresses, etc.) as well as

- alloy compositions.

Besides of material properties, eddy current inspection is suitable for inspecting geometric changes and material defects such as

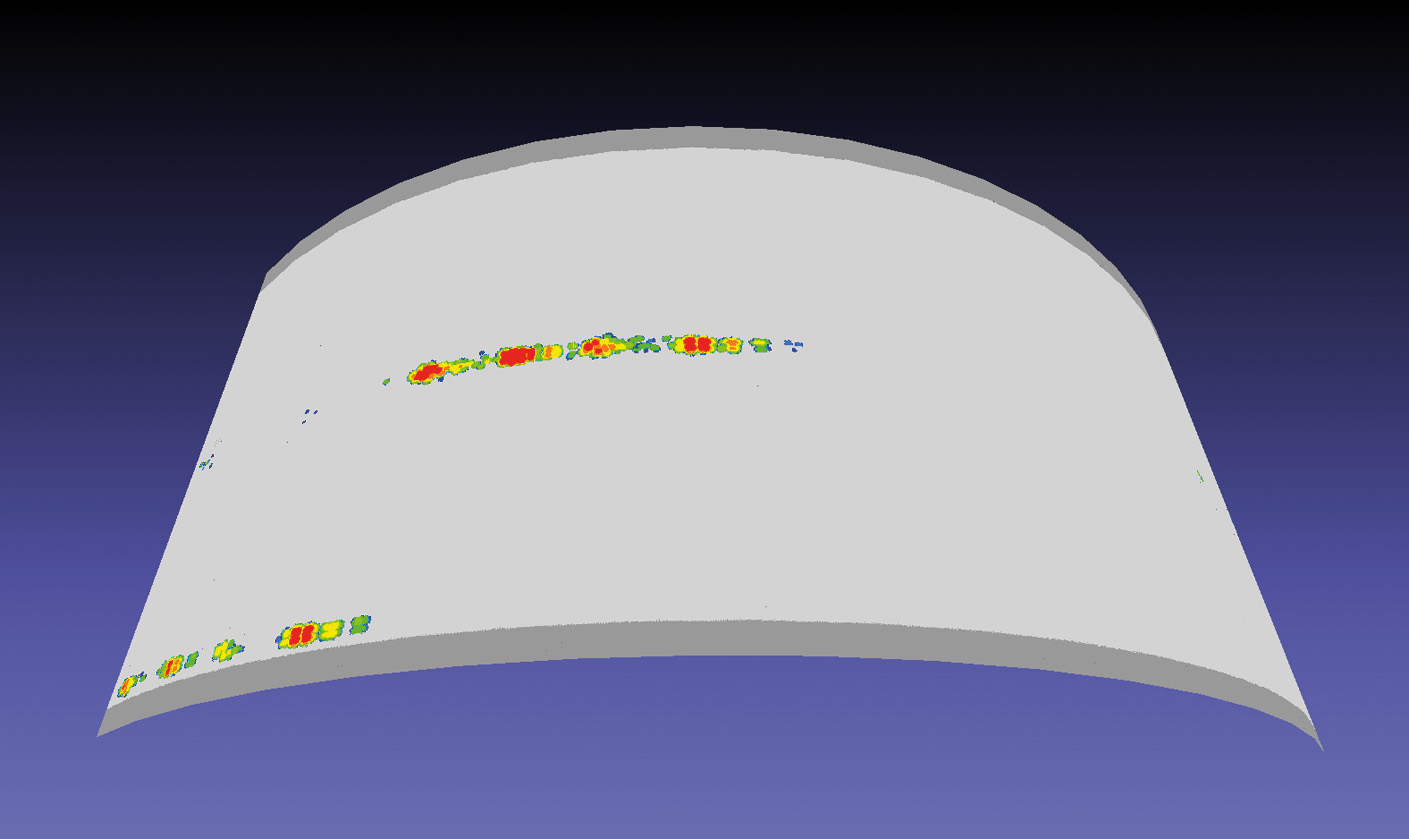

- CFRP fiber orientation, missing bundles and lane formation, delaminations, ondulations;

- surface defects, near surface and cavernous defects;

- lift-offs, layer separations, corrosive layers and sub-surface rust;

- diameter changes, e.g., in case of wires, rods, tubes or balls;

- thickness of both, metallic and non-metallic layers, even in case of multiple conductive layers.

“Industry 4.0“ provides an additional technological framework, viz. the digitization of industrial production by cross-linked intelligent systems. To this end, the fast integration of the respective systems via interfaces such as OPC UA is mandatory.

The goal was the development of an eddy current electronics flexible enough to be deployed in a wide range of applications. In this context, particular emphasis was to be given to the inspection of carbon fiber reinforced materials as well as to the challenges of the “Industry 4.0“ strategy.

The novel inspECT-PRO includes all components of an all-purpose eddy current inspection system. The electronics can be operated in single- or multi-frequency multiplex mode as well as in sensor multiplexing or in combination of both multiplex methods.

Important features include

- 2 parallel analogue hardware channels with the ability to generate different signals such as sinus/rectangle signal shapes as well as arbitrary signal forms

- Single- and multi-frequency operation with up to 32 inspection frequencies from 10 Hz to 112.5 MHz per hardware channel

- Multi-sensor operation with up to 32 sensors per hardware channel, realized by an external multiplexer for flexible positioning of the sensor-near electronics as well as far-reaching inspection distances

- Assembly of multi-channel systems by cascades of multiple inspECT-PRO electronics, enabled by the modular concept and adapted to customer requirements

- High sampling rate per channel: 125,000 samples/s (single-frequency mode), up to 1200 samples/s (multiplex mode) at 32 frequencies and/or 32 sensors; customized applications possible

- Integrated 3-axis coordinate and CTP interface (Cycle Trigger Pulse)

- Realtime inputs and outputs as well as OPC UA interface for data and process control

- Realtime signal processing and data assessment already on the inspECT-PRO electronics

- High-performance software for a great variety of inspection tasks with integrated regression analysis and classification algorithm

Applications

- Compact inspection system for top-hat rail mounting enabling easy integration into an electrical cabinet as well as control via OPC UA

- Mobile eddy current inspection system as a rugged industry notebook with IP65 protection class

- OEM kit comprising inspECT-PRO electronics and multiplexer for integration into customer systems

- Configuration of the inspection electronics according to customer requirements and integration into customer systems

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP