Modern and forward-looking manufacturing processes are essential building blocks for a company‘s economic success and efficiency. Production processes must be optimized continuously and intelligently under the aspects of resource savings, quality, and cost.

The ultrasound inspection system “WeldInspector“, a Fraunhofer IZFP development, provides unique options for the support and the optimization of the production processes of gearbox output shafts.

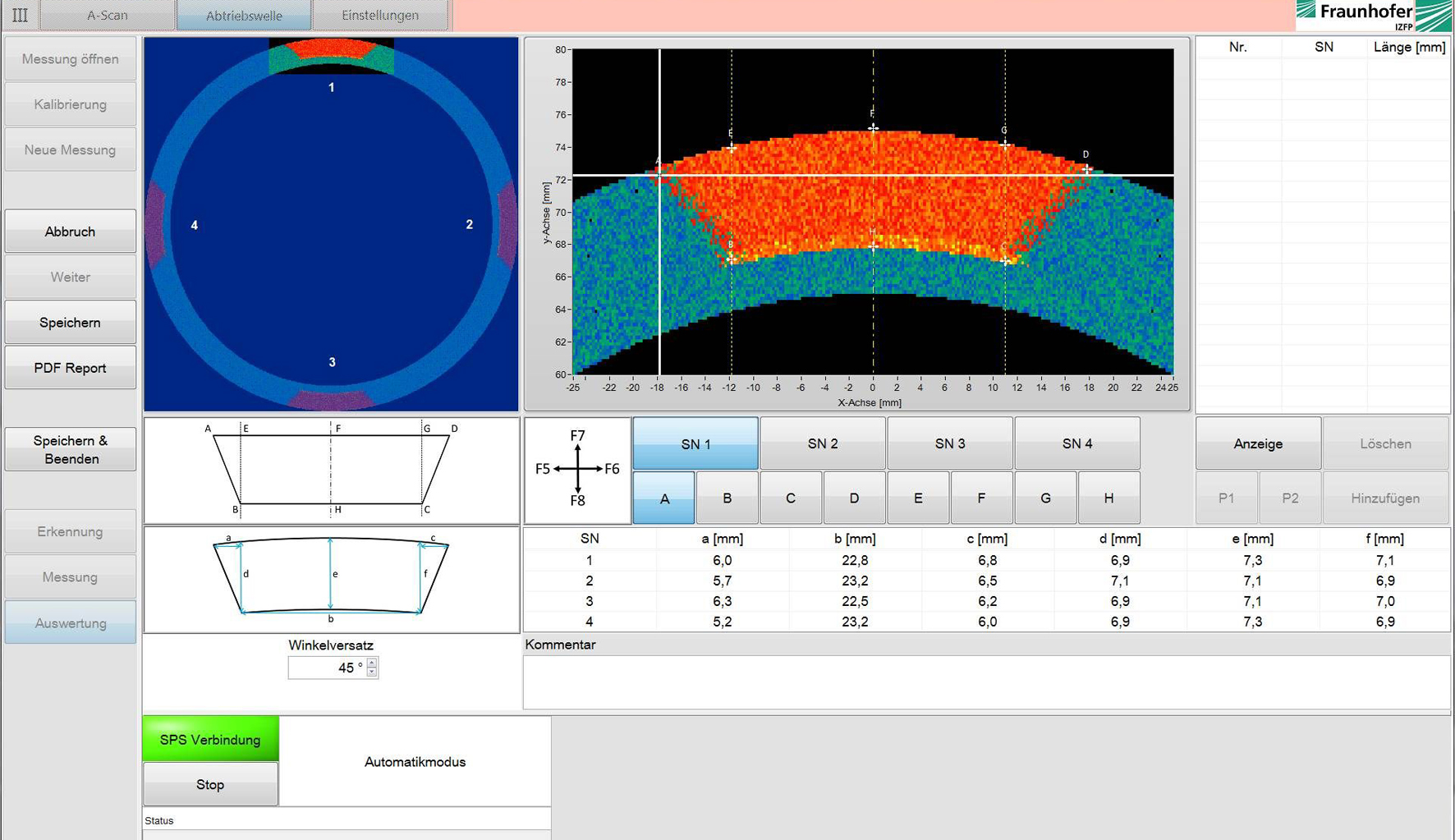

The system measures the entire weld seam geometry of the shafts at 100 percent within a few minutes by high-frequency ultrasound. This eliminates the need for the destructive metallographic examination of components that have been necessary at various stages of the production process.

Output shafts are manufactured by welding together different components. For different components, production lines have to be retooled. So far, the first two components had to be scrapped in product changeovers because they had to be prepared metallographically for the purpose of microscopic examination and for assessing weld seam quality. Another metallographic microsection grinding process was necessary for interim inspection. These processes required a significant amount of time and resulted in finished output shafts partially becoming test scrap. In addition to material savings, there is also a considerable reduction of inspection time.

After the component has been scanned by a QR code scanner, the appropriate inspection program is automatically selected on the basis of the code. The inspector then places the component in the test basin (inspection using immersion technique). Finally, the user-controlled weld seam measurement of the output shafts takes place within a very short time without any further set-up time.

The detailed evaluation and documentation follow immediately after the inspection by software developed at Fraunhofer IZFP. The partially automated device is able to measure 40 different types of shafts.

Benefits of “WeldInspector“

- 100 percent inspection: Comprehensive scan of all weld seams of the gearbox shafts

- Save on time and material: No metallographic inspection necessary

- Digital storage: Automatic documentation of the inspection results

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP