Our services

Fraunhofer IZFP develops and manufactures ultrasound sensors for diverse applications. The Institute has developed, among others, ultrasound sensors for the Rosetta mission, which launched on 2 March 2004 and landed on the cometary surface in November 2014.

Typically, however, we develop ultrasound sensors for material and component testing, as well as for condition monitoring over the entire product lifecycle from raw material to recycling.

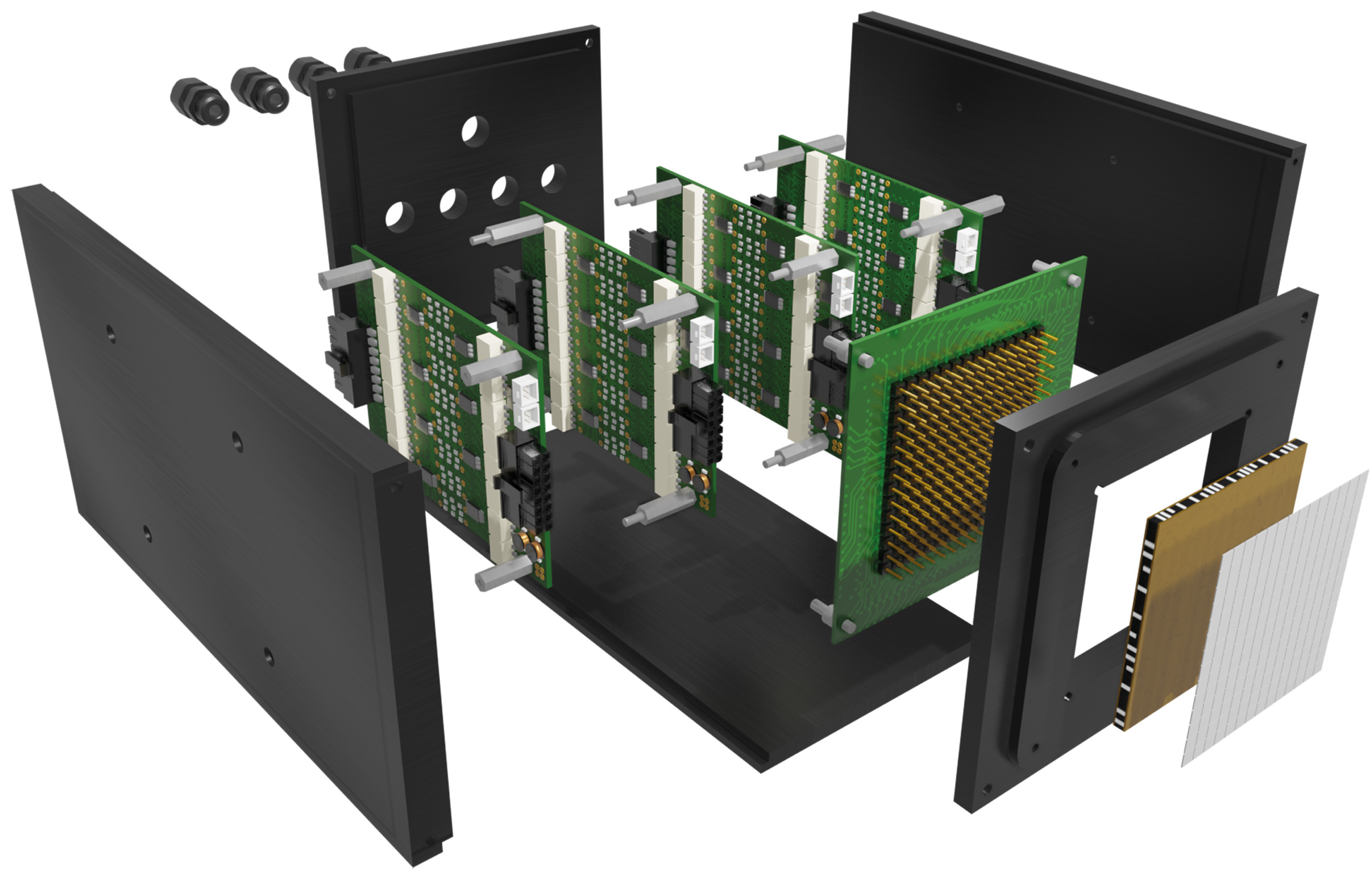

Ultrasound sensor systems

- Developing and building customer-specific ultrasound sensor systems for

- Immersion technology

- Contact technology

- Air-coupled ultrasound inspection

- Test frequencies from 50 kHz to 10 MHz

- Manufacturing prototypes and smaller runs

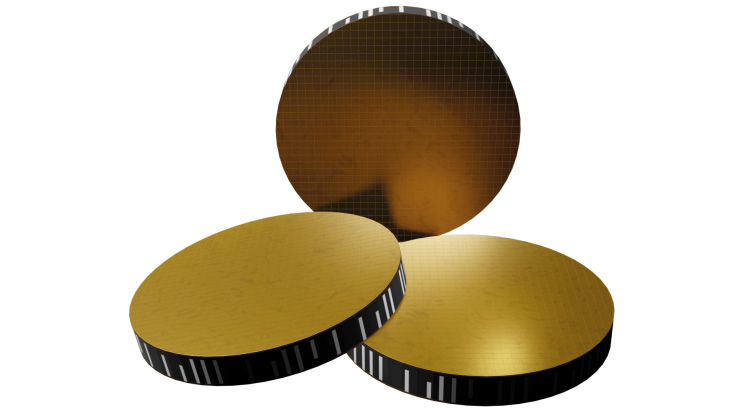

Manufacturing 1-3 piezocomposite materials

- Frequencies from 200 kHz to 8 MHz

- Mechanical impedances between 8 and 13 MRayl

- Max. dimensions up to 60 x 60 mm

- Machining to desired dimensions

- Choice of flat or focused transducers

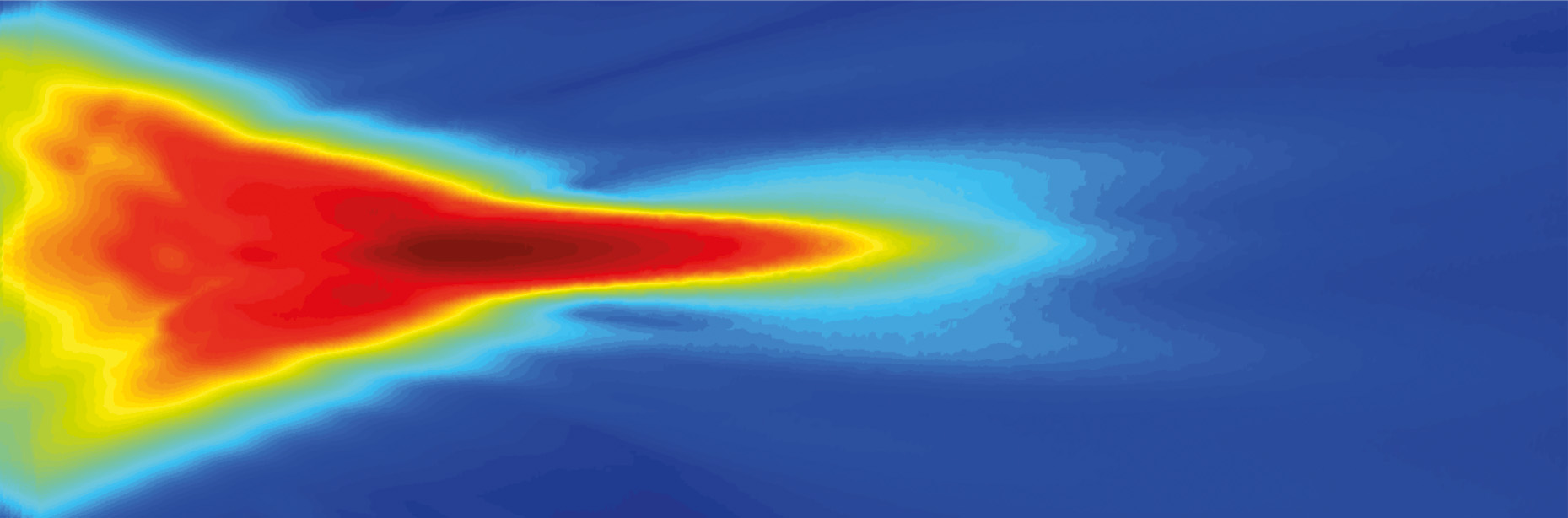

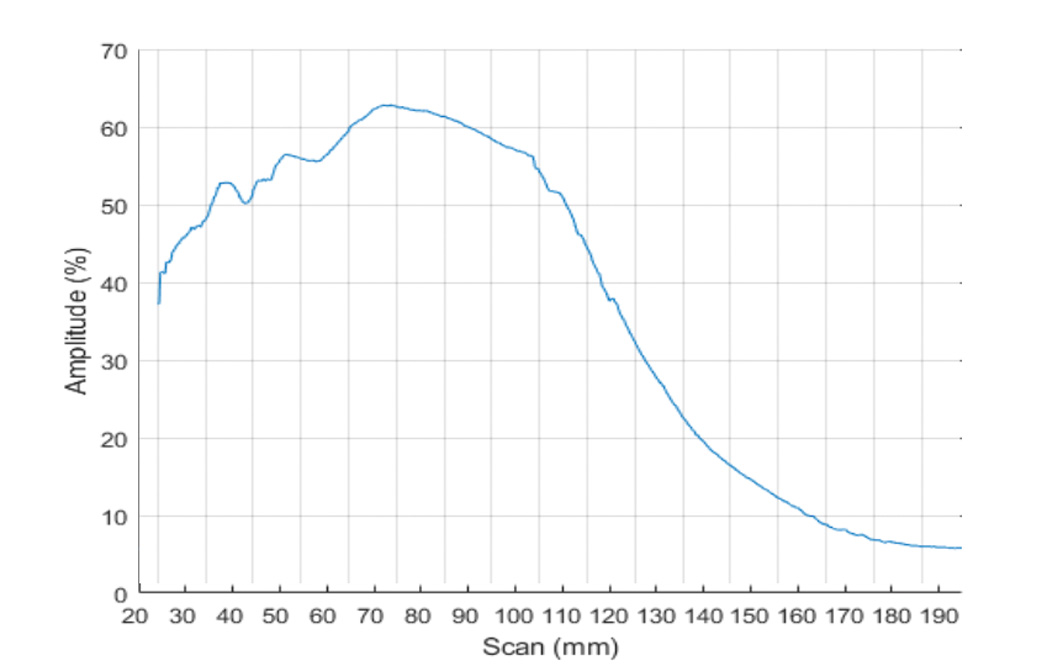

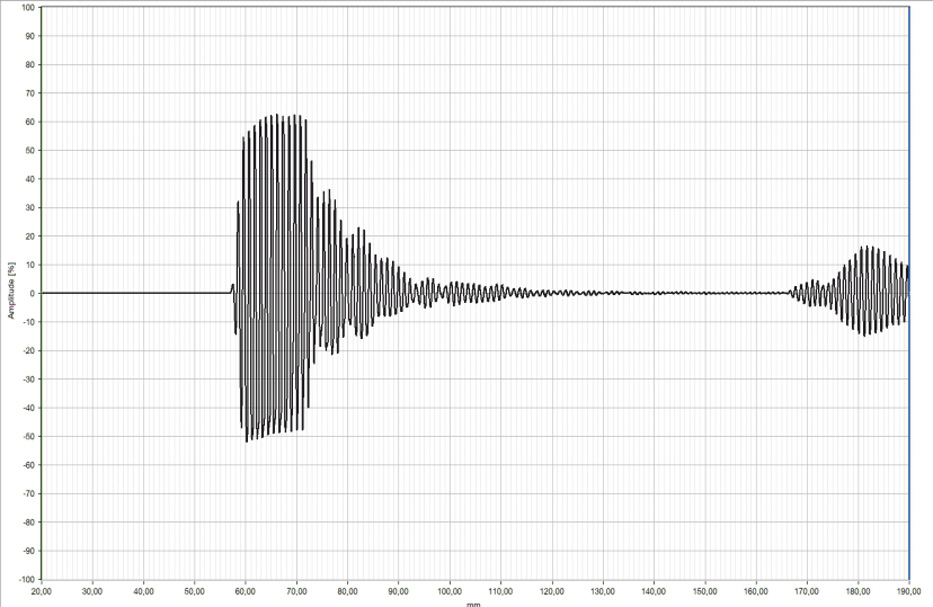

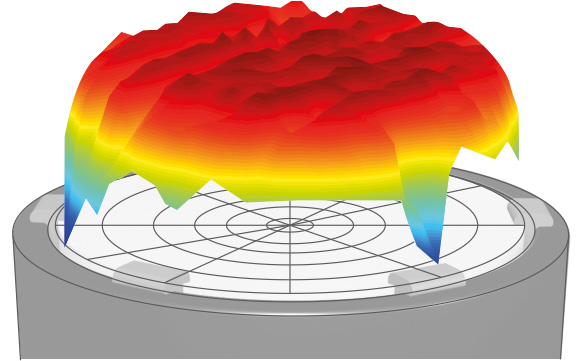

Extended characterization

- Characterization of the test heads according to current standards

- Visualization of the real sound field based on laser vibrometer data

Benefits

- High degree of reproducibility of the ultrasound sensor systems

- Short response times

- Customization to customer requirements

- Documentation for each test head

Flyer “Ultrasound sensors – custom-made“

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP