PlasmUS is the acronym for “Pulsed plasma-based contactless ultrasonic excitation.”

How can a new method for coupling-agent-free, contactless ultrasonic excitation be developed that is capable of generating ultrasonic waves with well-defined wave modes and high directivity even at greater distances from the material and in poorly conductive materials such as concrete?

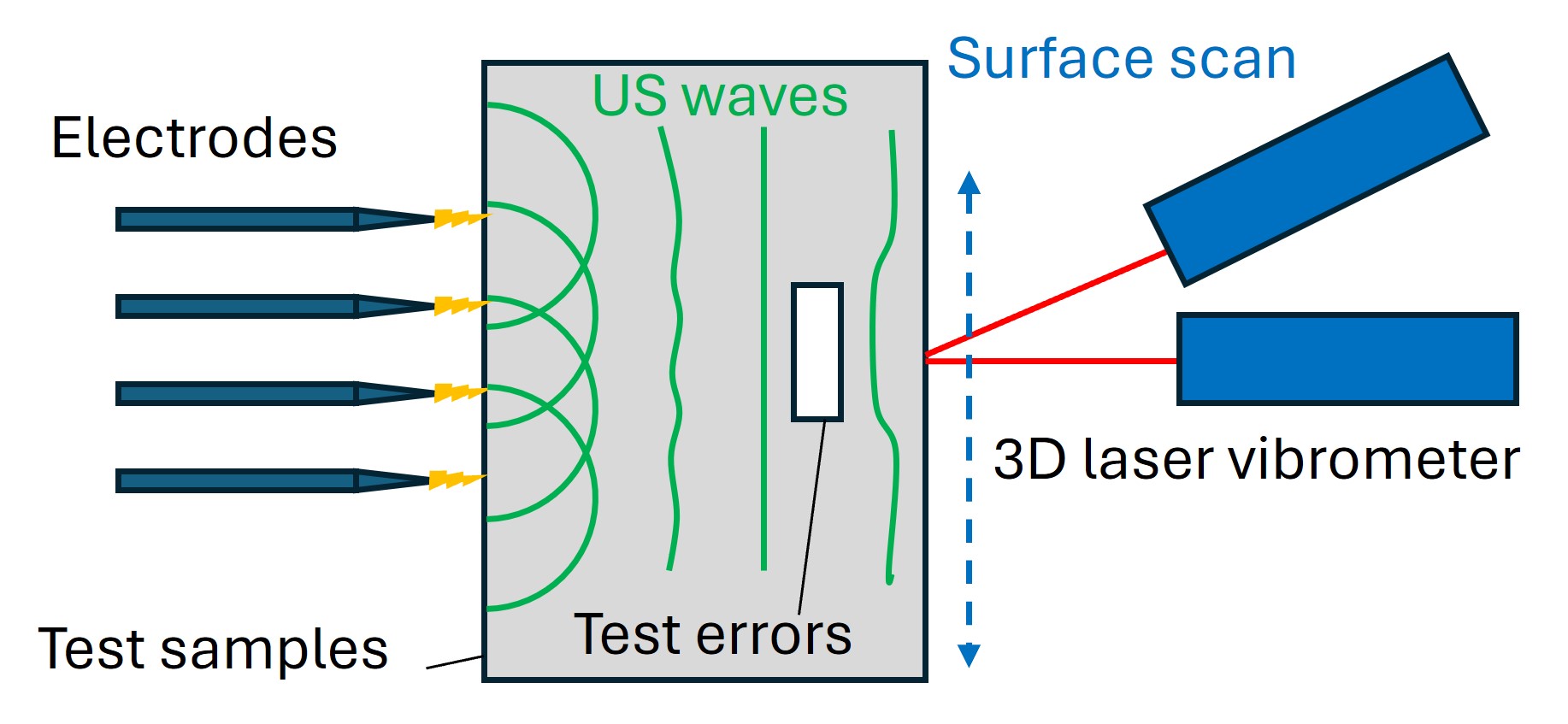

This leads to the central question of the project: The aim of the project is to develop a novel, contactless ultrasonic method that uses clocked plasma discharges on the component surface to excite acoustic waves in the material. The method is based on an innovative approach that is physically similar to electromagnetic ultrasonic technology (EMUS), but instead of magnetic induction, it uses pulse-like flash discharges. This also allows materials to be tested for which EMUS is unsuitable due to low electrical conductivity (such as concrete).

An array of several synchronized plasma sources is used to precisely control the wave mode and direction of propagation. This generates constructively interfering ultrasonic waves, whose directional characteristics can be controlled by software. This opens up a new avenue for nondestructive testing, offering a solution in particular for large, hot, coated, or irregularly shaped test objects where conventional ultrasonic techniques reach their limits.

The technical implementation will take place in several steps: First, the physical fundamentals of plasma excitation and the resulting wave modes will be simulated using multiphysics. An experimental laboratory setup is then implemented to characterize the generated sound fields. Finally, testing is carried out on test specimens with defined test defects.

The project is investigating a previously unrealized method of contactless ultrasonic excitation that is highly innovative in terms of both its physical mechanisms of action and its technical implementation. The successful completion of the project lays the foundation for further application developments, e.g., for testing systems in foundries, in building monitoring, or in quality assurance for thermally stressed components.

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP