GrenzQualifizierung is the short title of the project ”Rechnergestützte Beurteilung der Bauteilfestigkeiten auf Basis virtueller Grenzmuster” (Computer-assisted assessment of component strength on the basis of virtual limiting samples).

Large castings made of spheroidal graphite iron (SG) offer indispensable advantages for the wind energy sector as well as for the construction of large machines and plants due to the high degree of creative freedom and the low manufacturing costs. The increase in performance of plants with simultaneous resource-saving processing requires increased material utilization and places special demands on the knowledge of cyclic material behavior. In this context, there have always been large gaps in the linking of casting simulation, construction, fatigue design measurement and nondestructive quality assurance concerning the design, construction, dimensioning and quality assurance especially of thick-walled components.

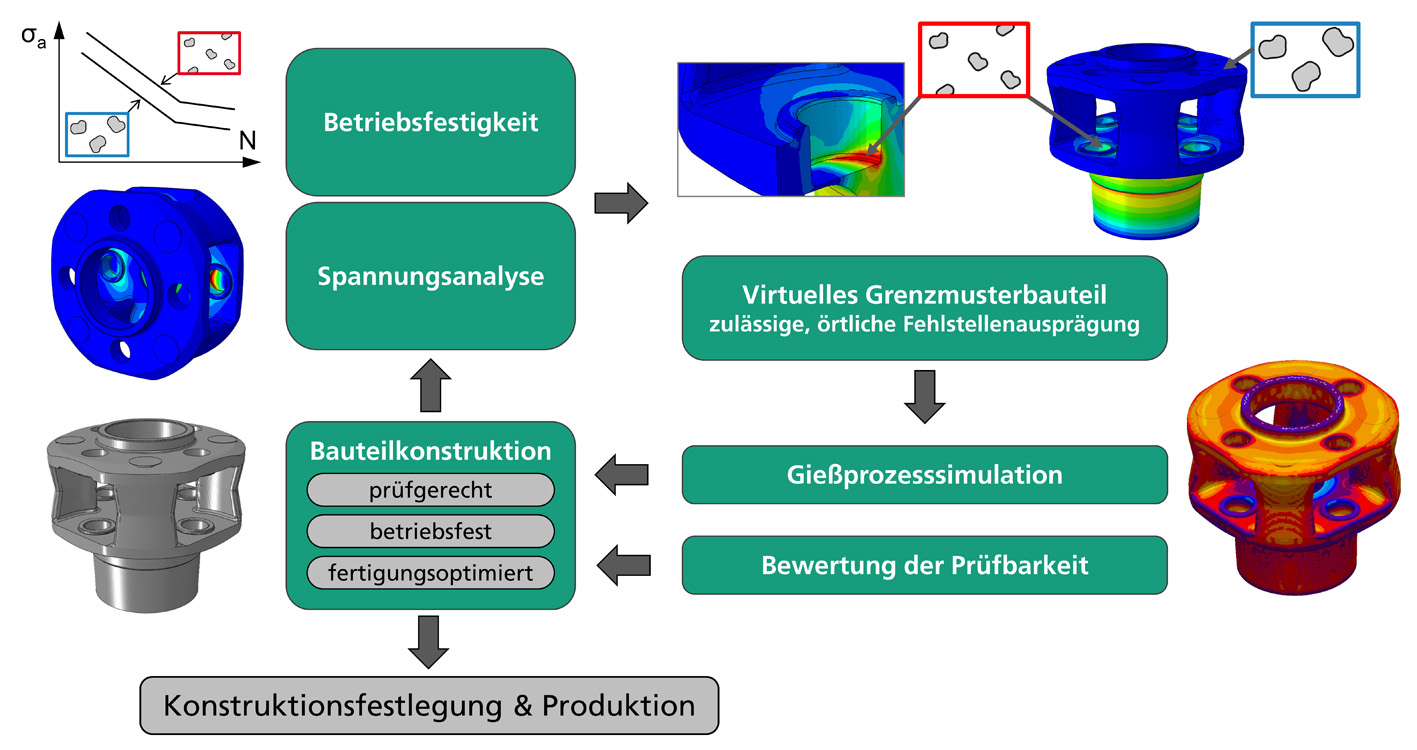

Since inside the casting the occurrence of imperfections such as discontinuities (e.g. dross, blowholes) and microstructure degenerations such as chunky graphite cannot be ruled out due to the manufacturing process, tools are required that allow fast and documented decisions whether and where these imperfections are permissible in the component. Taking into account component-specific stress situations, down to the present day there is a lack of options to precisely describe the effect of the found imperfections on the structural durability of large cast components.

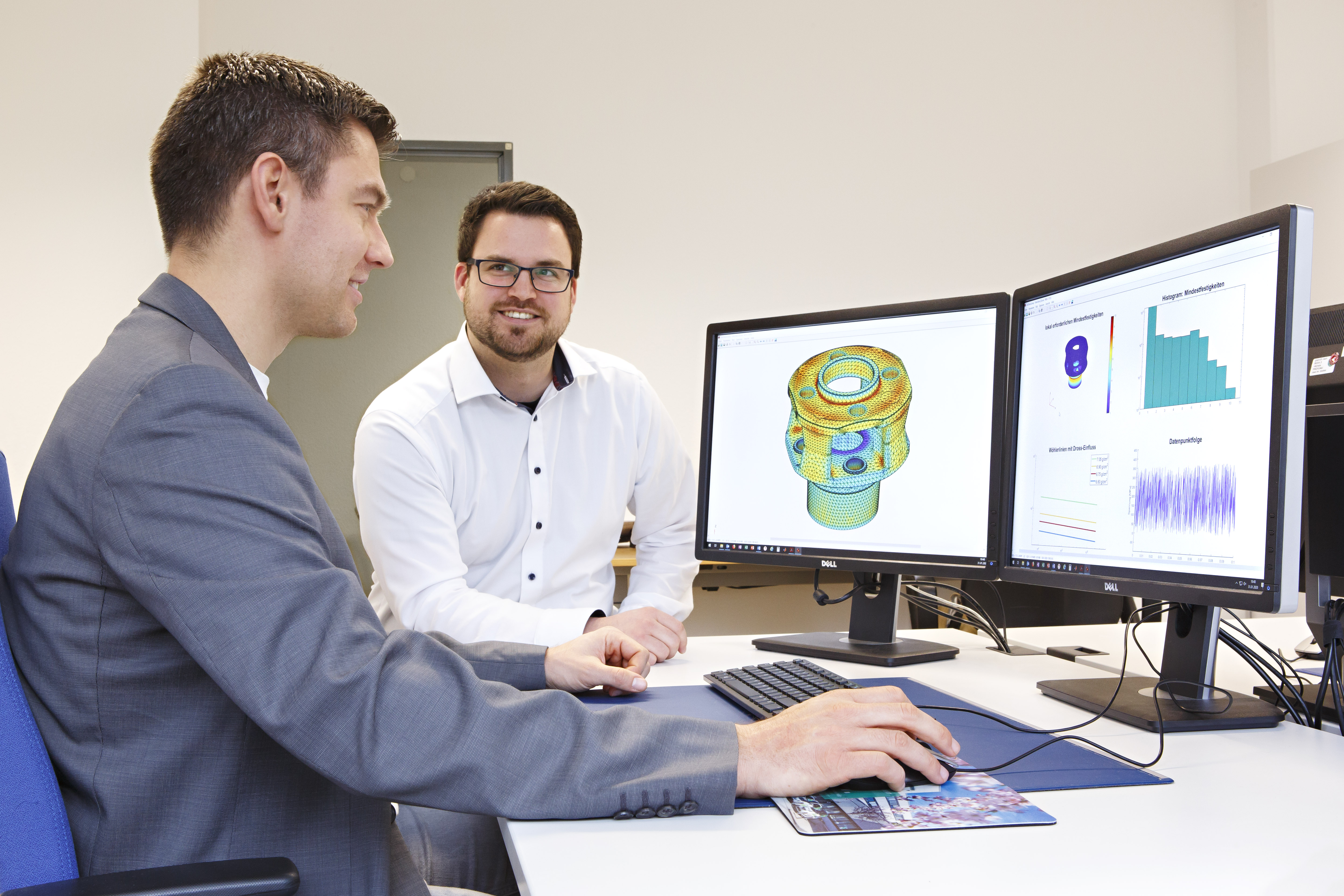

The GrenzQualifizierung project is working on the development of such a method to derive virtual limiting samples for practical application. The virtual limiting sample indicates permissible defects for all component areas depending on the local load and the service life requirements. As information on locally permissible imperfections is already stored in the virtual limiting sample, a significantly simplified test procedure can be used for quality assurance and a reliable decision can be made as to whether or not a component is to be rejected. To this end, casting simulations, component dimensioning and nondestructive quality assurance have to be digitally cross-linked in the sense of Industry 4.0.

The project focusses on the microstructure degeneration of chunky graphite as well as the ”dross” discontinuity in different casting materials (EN-GJS-700-2, EN-GJS-400-18, EN-GJS-450-18, EN-GJS-1050-6 (ADI)) including their effect on the local vibration strength. For this purpose, Fraunhofer IZFP is developing a method to detect chunky graphite on both, test specimens and real components using magnetic and acoustic nondestructive testing methods. Furthermore, methods are evaluated to assess the nodularity of spheroidal graphite.

The consortium comprises the following institutions, which are active in various ways in the field of casting materials:

- ACS Solutions GmbH

- BMB Gesellschaft für Materialprüfung mbH

- Fraunhofer Institute for Structural Durability and System Reliability LBF (Coordinator)

- Fraunhofer Institute for Nondestructive Testing IZFP

- MAGMA Gießereitechnologie GmbH

- Siempelkamp Gießerei GmbH

- Meuselwitz Guss - Eisengießerei GmbH

- ZF Wind Power Technology

- ZWP Anlagenrevision GmbH

- Eickhoff Gießerei GmbH

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP