During operation, machines or systems generate characteristic vibrations and noises. Changes in these noises provide information on assembly errors or other defects. Human hearing is limited in its capability to detect these changes due to a certain amount of subjectivity as well as personnel fatigue or interference from ambient noise.

Acoustic testing systems available on the market allow objective detection of unusual vibrations or noises. However, such systems have often to be carefully and explicitly calibrated using representative parts. In addition, the acoustic and vibratory behavior is generally limited to few parameters such as frequencies or amplitudes. Even minor design adjustments will require recalibration to prevent a negative impact on testing reliability.

To solve these problems, Fraunhofer IZFP has developed “AcoustiX“, an acoustic sensor system based on cognitive signal analysis.

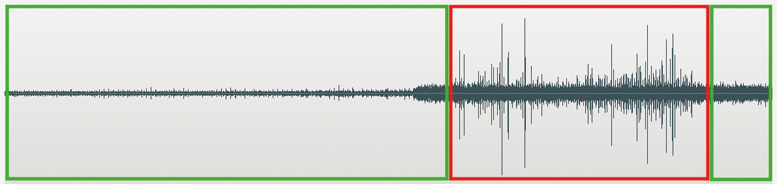

The cognitive approach resembles subjective noise evaluation by humans; however, it provides objective and reproducible results. The actual process involves using appropriate sensors for detecting and digitizing operational vibrations and/or noises, followed by segmenting them into short time intervals, filtering and converting them. Finally, successive signal segments are compared using appropriate mathematical methods.

Unexpected vibrations or noises will result in characteristic differences for the segments. This will be pointed out by the system correspondingly. The algorithms developed do not require prior knowledge, except for a few reference signals required for the initial software calibration. Thus, the algorithms will detect anomalies without requiring complex teaching.

Advantages

- High testing reliability due to objective, simultaneous evaluation of the signals from multiple sensors

- Cognitive quality evaluation without explicit calibration

- Versatile application, e.g., for final assembly inspection or for permanent quality monitoring

- Fast inline evaluation: Instant detection of irregular products

- Individualized system setup: Customized testing hardware design and evaluation algorithms

- Option for integrating the evaluation algorithms into existing testing systems

- Onsite feasibility studies using a portable sensor system

- User-friendly and customer-specific adapted operator software:

- User-friendly display of test results in the operator and evaluation software

- Standard results display by means of traffic light indicators; no need for comprehensive training

- Versatile software functions

Applications

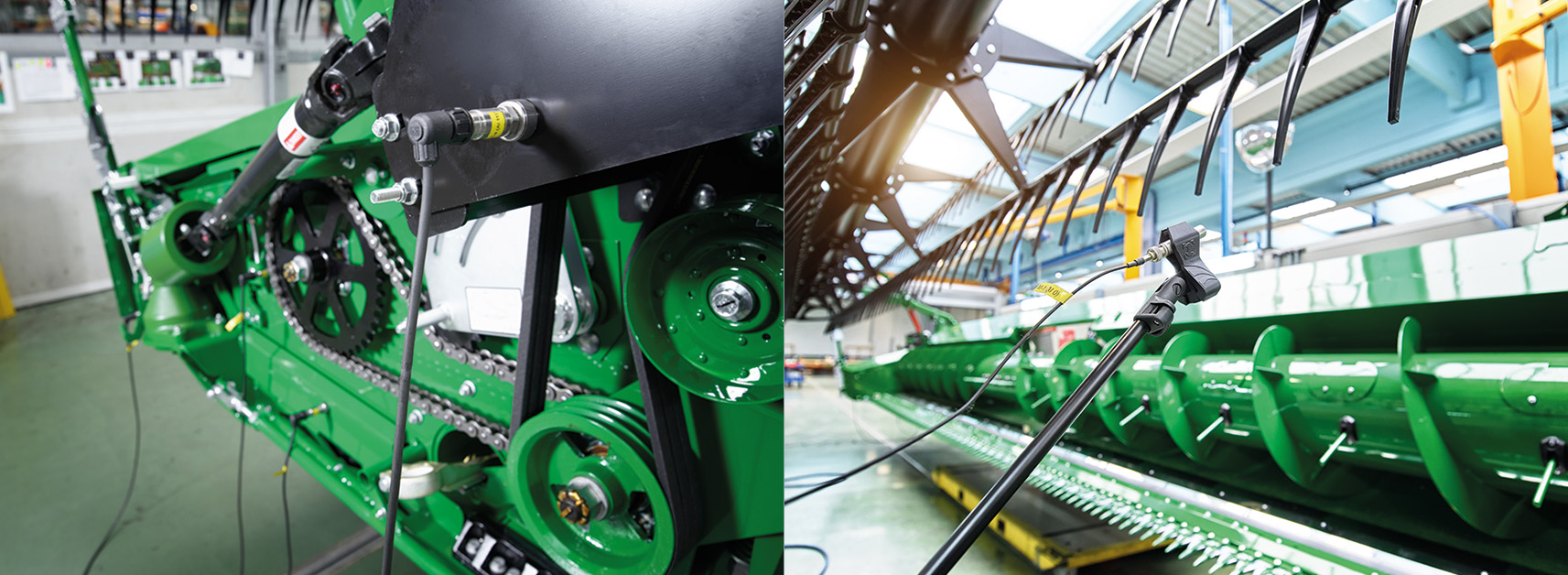

- Final assembly inspection of machines or systems with moving parts

- Monitoring operations at regular time intervals, or permanent quality monitoring: Monitoring large, autonomously operating machines and systems

- Evaluating the quality of individual assemblies being operated, e.g., on test benches

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP