Steel manufacturing and steel processing industries require nondestructive testing methods for quality control, e.g. regarding hardness, case depth, strength and residual stresses. Ferromagnetic steels and cast iron show a distinct correlation between magnetic behavior und mechanic-technological material characteristics. Hard-magnetic materials mostly show mechanical hard and brittle characteristics, while soft-magnetic materials such as pure iron use to be mechanical ductile. Residual and load stresses exert a comparable influence on magnetic processes. Hence, in many cases magnetic properties can be used to analyze mechanical material behavior and stress states.

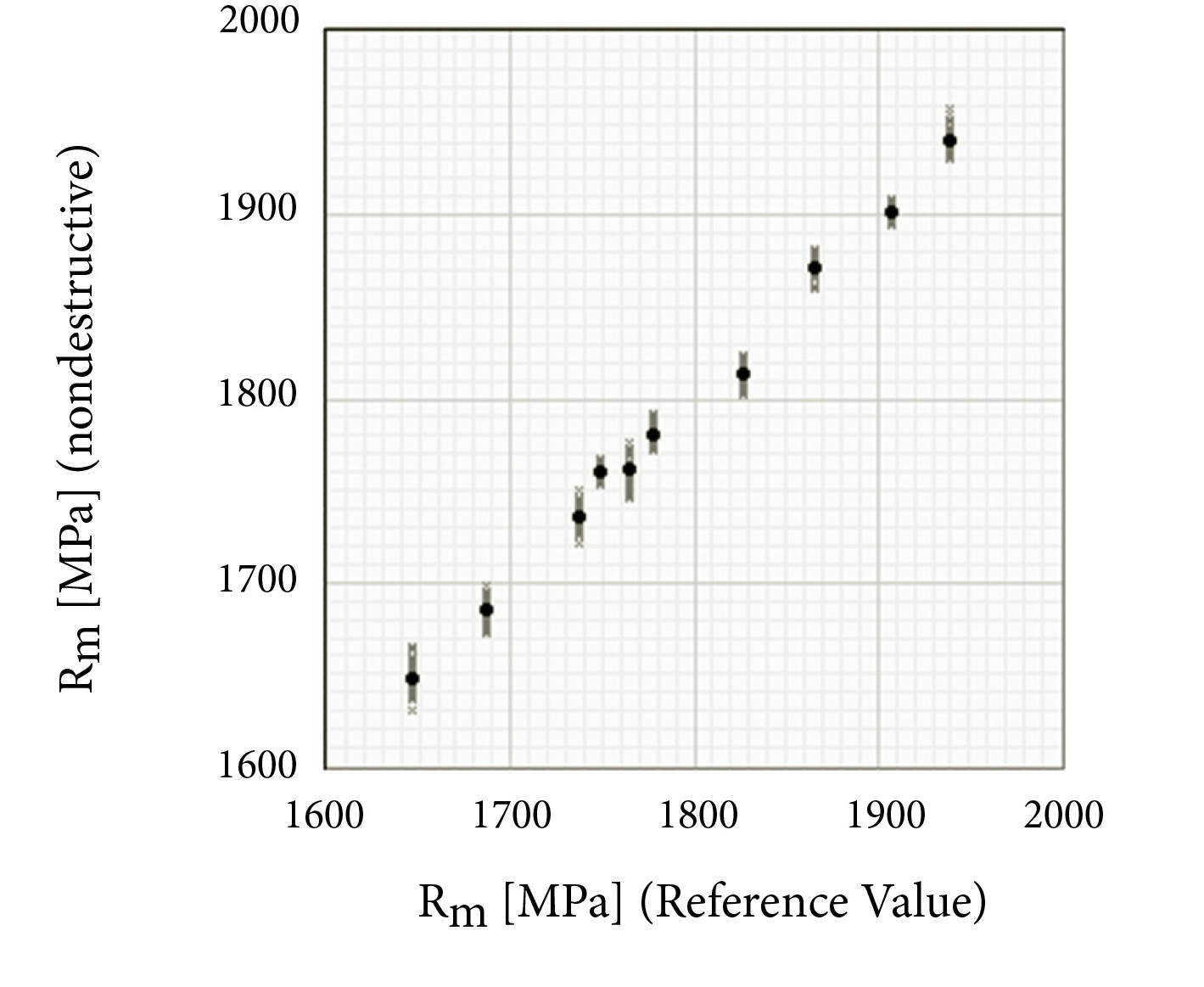

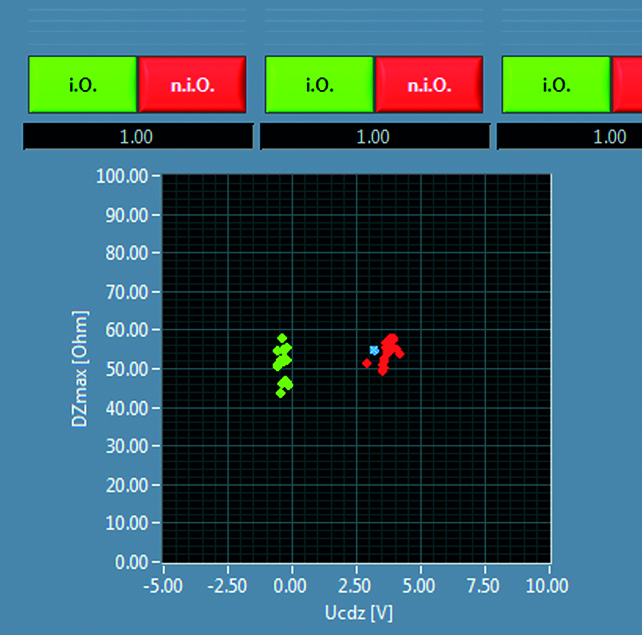

3MA is the acronym for “Micromagnetic Multiparameter, Microstructure and stress Analysis“. 3MA testing systems measure in fractions of a second not only a variety of magnetic parameters reflecting different material properties as well as residual and load stresses, but also how soft or hard magnetic a material is. The method uses a defined set of calibration samples as well as pattern recognition and regression analysis to determine the correlation between the magnetically measured characteristics and the target quantities required by the customer. Finally, the calibration can be used to inspect calibrated types of assemblies, components or semifinished products.

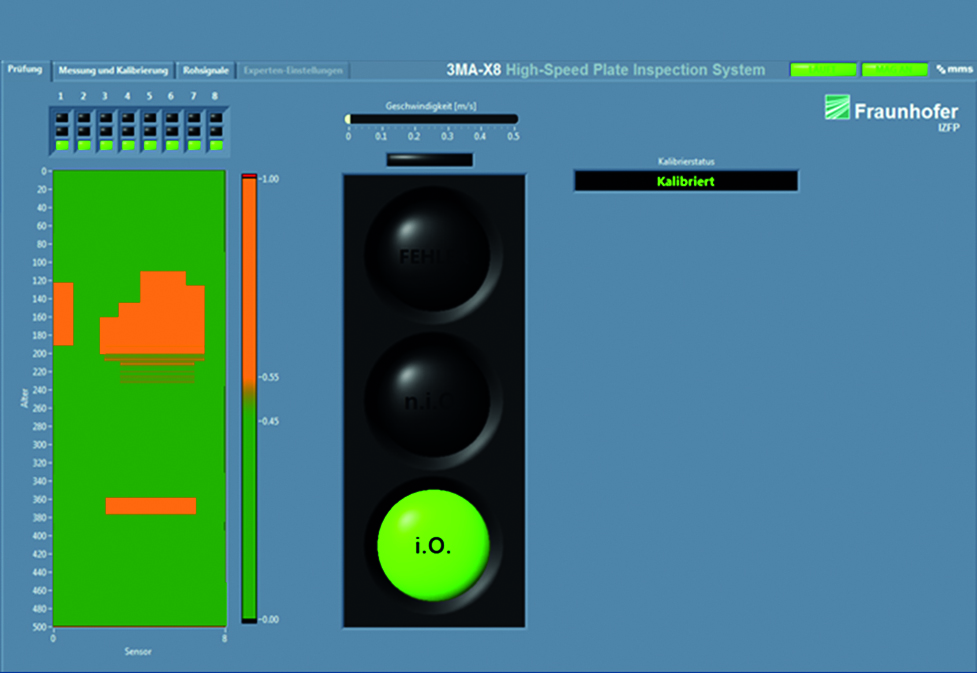

The 3MA-X8 inspection system is a 3MA variation especially zeroing in on easy calibration, high measurement velocity and variable sensor shaping. Additionally, the parallel operation of up to 8 sensors in one device is possible, thus allowing to deal with multiple measuring positions at same time or to accelerate area scans.

Applications

- Determination of hardness, case depth, tensile strength, yield strength, breaking elongation, residual and load stresses

- Confusion check

- Determination of dross in cast materials

- Detection of deviations in local material property

- Inspection of assemblies and components, even parallel at several positions

- In-line real-time measurements in production processes

Features

- Test method: 3MA with variants of

- Analysis of upper harmonics

- Analysis of eddy current impedance

- Analysis of eddy current incremental permeability

- Maximum 8, standard 3 sensors per device, area scans with up to 8 sensors simultaneously

- Magnetization frequency: 10 Hz – 1000 Hz

- Eddy current test frequency: 100 Hz – 20 kHz

- Measuring velocity identical with magnetization frequency

- Support for different sensor dimensions

- Easy calibration for o.k. / n.o.k. distinction

- Port for incremental position sensor

- Digital and analog I/O optional

- 3MA sensors at hand can be used with an adapter

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP