BiWa-MOS is the acronym for ”Bildgebende Werkstoffanalyse mittels MagnetoOptischer Sensorik zur schnellen Qualitätssicherung von Stahlbauteilen” (Imaging material analysis by using magneto-optical sensor technology for fast quality assurance of steel components).

Imaging techniques capable to find imperfections in components and assemblies have always been in demand, as they offer, comprehensible evaluation possibilities and adequate data for machine evaluation. This is one of the reasons why imaging procedures such as X-ray computed tomography are highly valued and often used in quality assurance. Other methods, such as thermography, offer cost-efficient and safer ways for imaging examination, up to visualization of macroscopic material changes. A wide range of new possibilities would arise by making processes visible in a non-invasive manner on a microstructure level. Techniques that are able to generate real time ”vivid” images of changes in microstructure, stress distributions, fatigue processes and similar phenomena offer undreamt-of possibilities beyond defect inspection to understand and control material behavior in detail. Material and product development can be accelerated and image-based parameters can be incorporated into digital production processes by real time feedback and visualization of the material condition. Possible applications comprise the visualization of stress fields in components, the surveillance of plastic deformation under mechanical load as well as film recordings of the transformation phase.

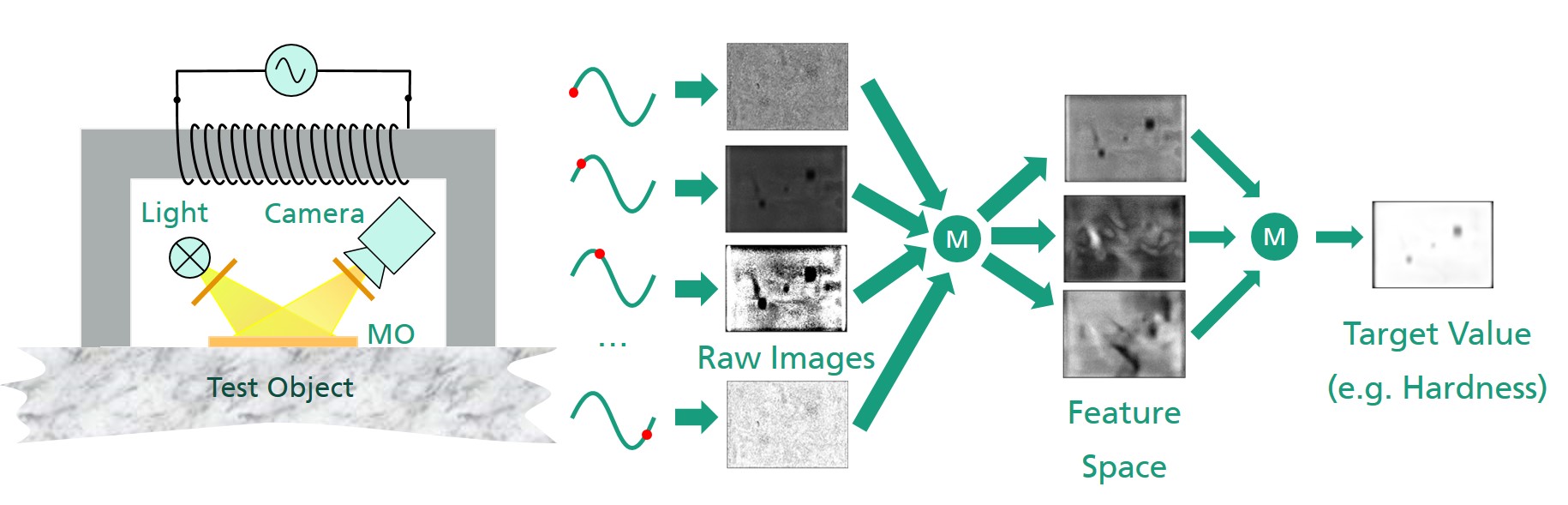

The objective of the BiWa-MOS project is the development of a novel method for the extraction and computational processing of parameters from magneto-optical (MO) images. These images are generated by MO sensors for the immediate visualization of the surface distribution of material properties. The innovation of the project consists in combination of state-of-the-art aspects of magneto-optics with those of micromagnetics and application of optical technologies in the field of quality assurance. Magneto-optics deals with effects that relate to the rotation of the polarization angle of light in or on media as a function of magnetic fields. To this, a nondestructive MO sensor will be further developed and tested, that records the distribution of material properties in seconds with a near-surface spatial resolution better than 50 µm, down to a depth of approx. 1 mm subsurface.

This project is funded by the German Federal Ministry of Education and Research (BMBF) as an individual research project in the framework of the ”WiVoPro” funding initiative (Wissenschaftliche Vorprojekte – Scientific Pre-Projects) within the research program ”Photonics Research Germany”.

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP