Application for surface hardening

- Surface hardening optimization

- Improving fatigue resistance and roller strength through compressive residual stress

- Friction properties optimization

- Improving wear and corrosion resistance

For high-quality surface hardened products, it is crucial to manufacture a hardened layer with a defined thickness. Without nondestructive methods, quality assurance requires destructive testing of

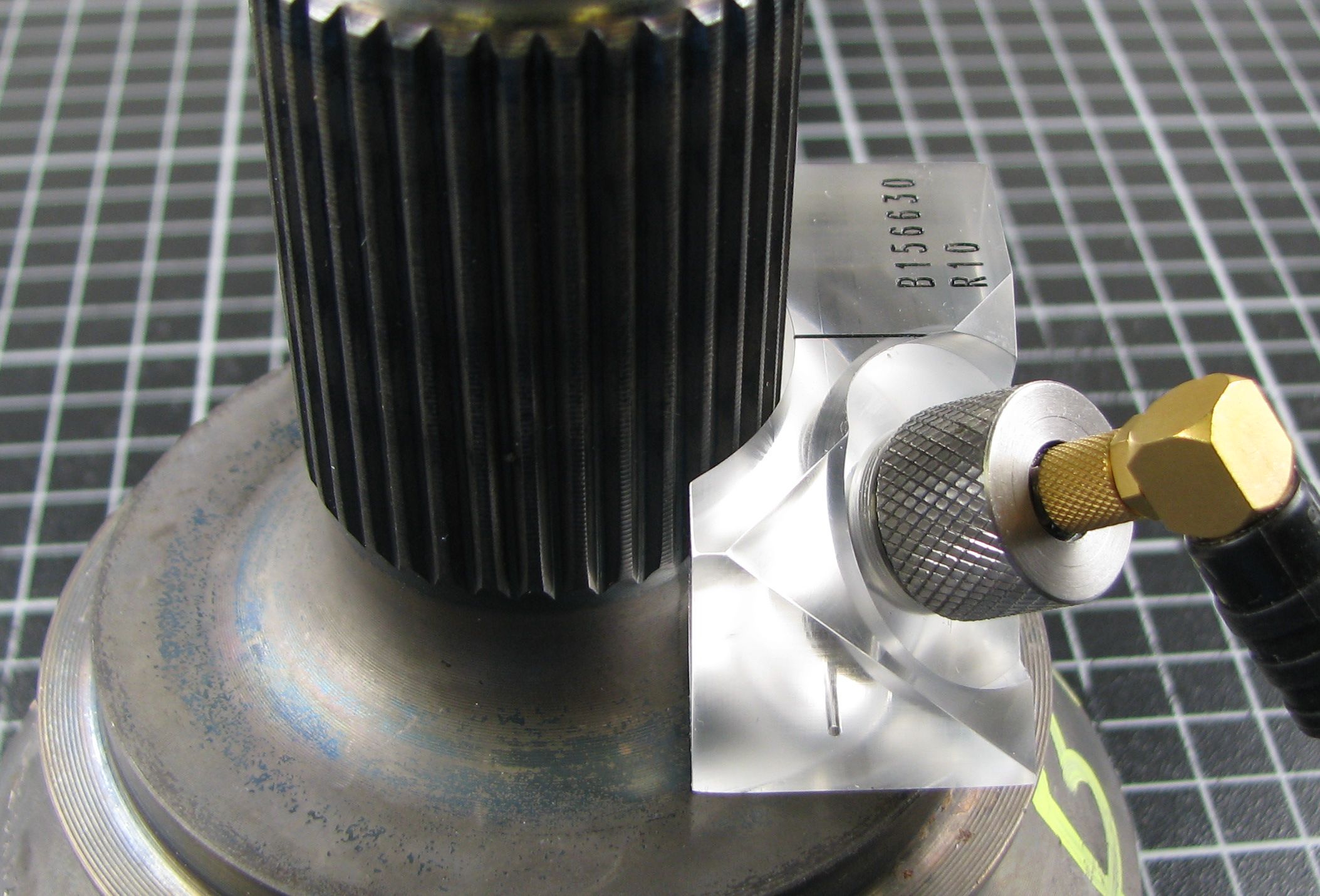

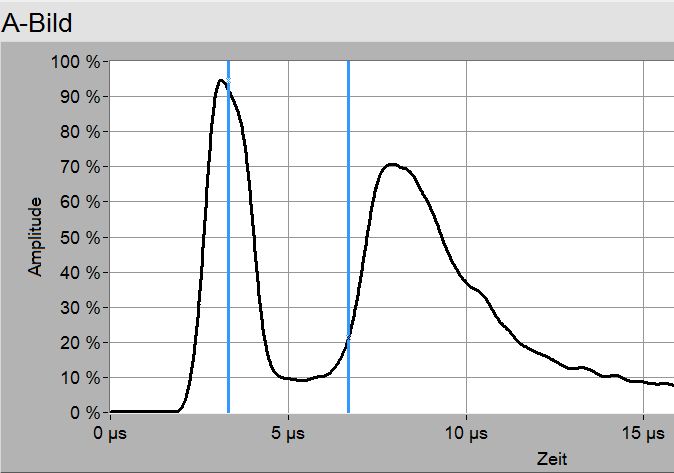

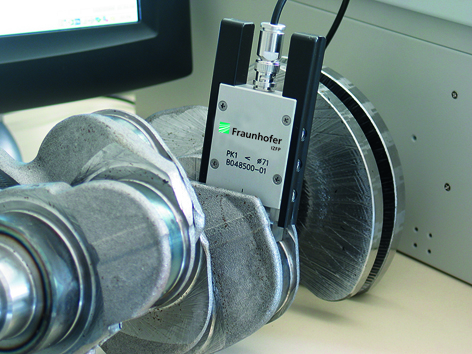

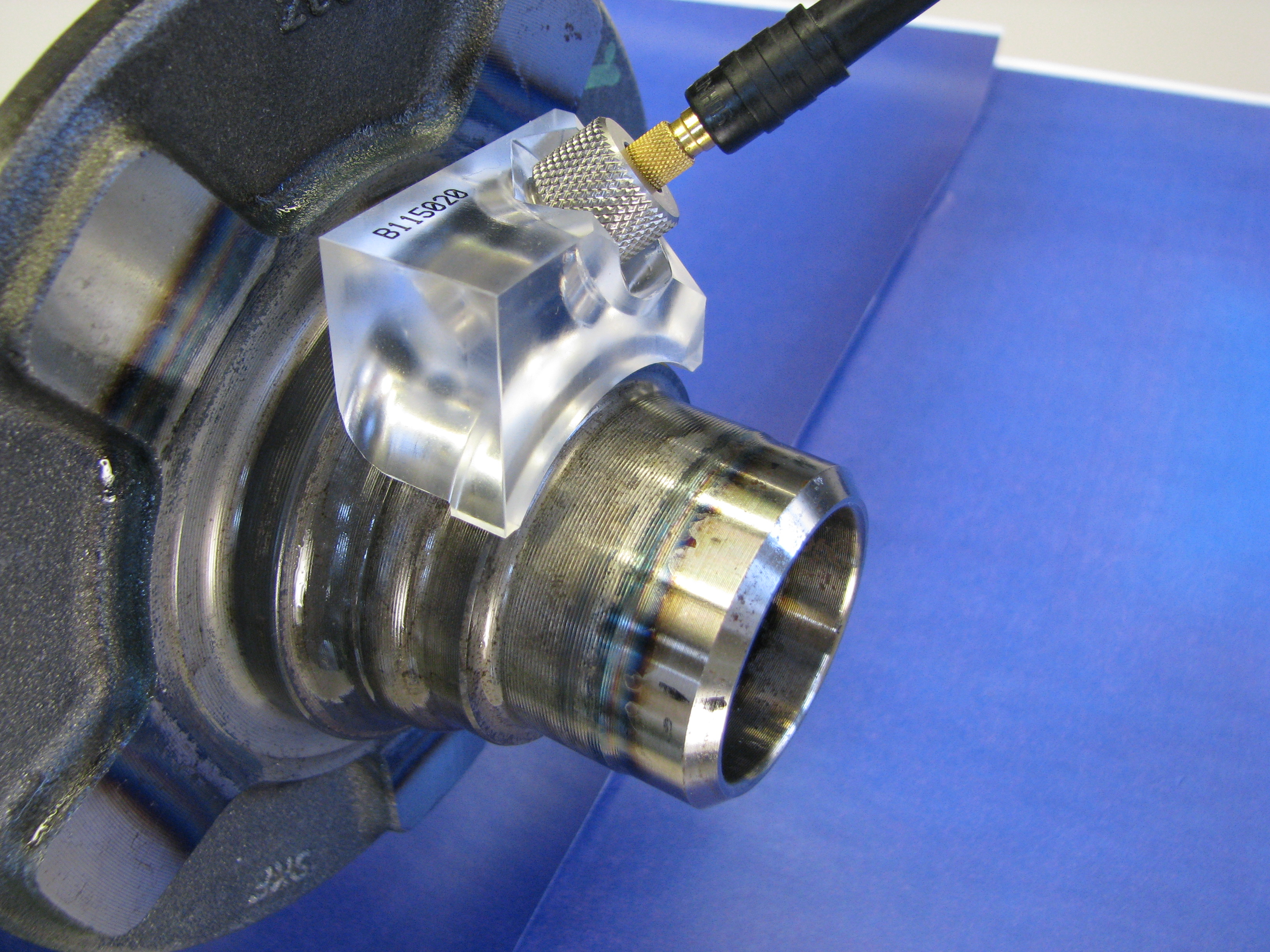

random samples, a time-consuming and costly approach with relatively low throughput. As an alternative to destructive techniques such as optical analyses or hardness depth profiling, SHD is determined with ultrasonic time-of-flight measurement. This nondestructive technique uses backscatter signals out of the transition zone between hardened layer and base structure, which represent the corresponding hardening depth. Using the mechanical and structural differences between the microstructures of the surface hardened layer and the base material, in combination with ultrasonic frequencies optimized for backscattering, the customer achieves reliable and reproducible SHD measurements.

With measurement systems that rely on this effect, the SHD is determined by the ultrasonic time-of-flight evaluation between the surface-signal and the backscatter-signal from the transition zone. Considering the material-specific ultrasound velocity, the SHD is calculated directly. This state-of-the-art ultrasonic SHD method is in high demand in the energy sector, in the production of large roller bearings and in the manufacture of truck and automobile crankshafts. Our innovative technology is also making inroads in other industries for customized solutions.

Requirements

- Tight microstructure gradient between hardened layer and base structure

- One-off feasibility study of “good components“ for comparison purposes

Benefits

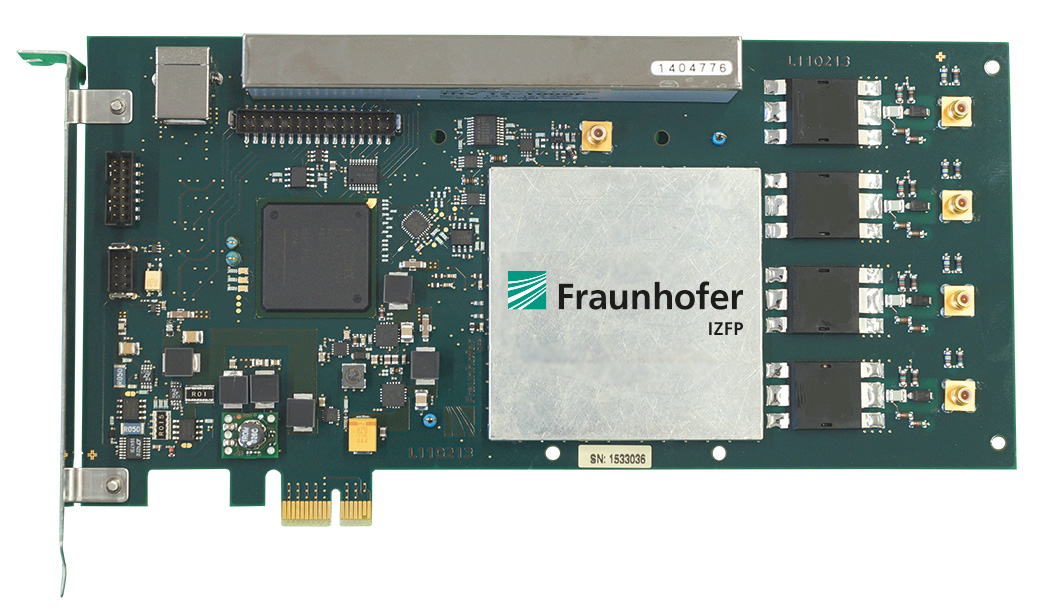

- Fraunhofer IZFP has more than 30 years of experience with customized ultrasonic hardware and software

- Fraunhofer IZFP designs and manufactures optimized ultrasonic electronics

- Systems for automated (Fraunhofer IZFP) and manual testing (via partners) are available

- No calibration of reference parts with defined hardness

- Impartial, user-independent measurement technique

Flyer “Surface Hardening Depth (SHD)“

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP