Iron and steel parts are often made from ferromagnetic materials. They are thermally treated and machined to create functional characteristics. Determining the quality of the surface layer properties requires suitable inspection methods. Micromagnetic methods offer a fast, nondestructive way to characterize and analyze materials with up to 100 percent process integration.

Micromagnetic inspection systems

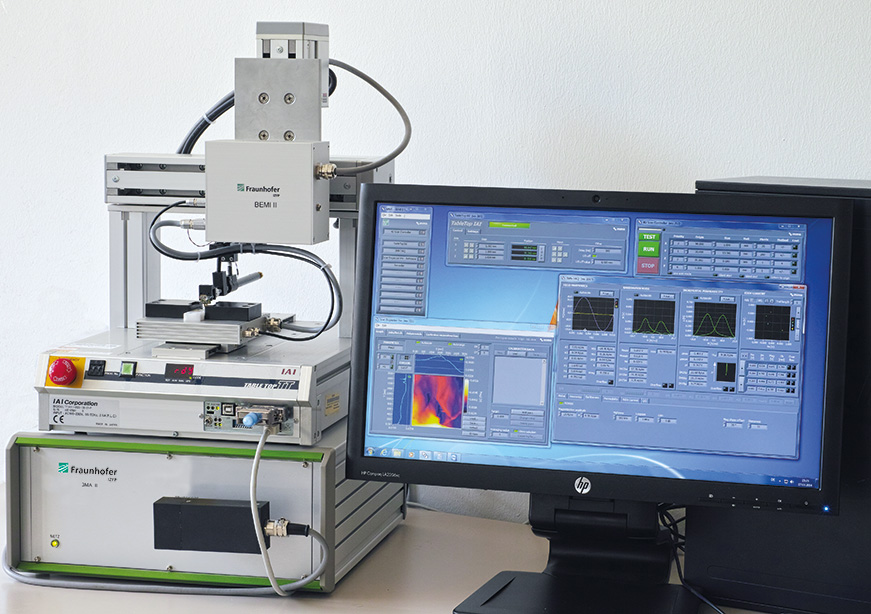

- 3MA-II (Micromagnetic Multiparameter, Microstructure and Stress Analysis): High-performance system for material characterization

- 3MA-X8: Simple calibration, high measuring speed, flexible sensor shaping, concurrent operation of several sensors with a single inspection device

- BEMI (Barkhausen Noise and Eddy Current Microscope): 3MA with special high-resolution sensor; scanner for determining material characteristics

Functionality

The systems combine four micromagnetic methods:

- Harmonic analysis in the time signal of the tangential magnetic field strength (3MA-II, 3MA-X8)

- Magnetic Barkhausen noise analysis (3MA-II, BEMI)

- Incremental permeability analysis (3MA-II, 3MA-X8, BEMI)

- Eddy current impedance analysis (3MA-II, 3MA-X8, BEMI)

Carrying out these methods at multiple frequencies supplies more than 40 micromagnetic parameters representing the characterization of the material structure. By combining these parameters, production issues such as batch fluctuations and tolerances can be easily managed. One-time calibration using defined component conditions is required for the quantitative determination of the material characteristics. Common target parameters are:

- Hardness, hardness depth

- Layer thickness and layer properties

- Residual and load-induced stress

- Microstructures

- Tensile test values

Examples of application

- Quality assurance for induction, case, press, nitride, laser, electron beam hardening processes

- Grinding burn characterization

- Detection of thermal treatment defects

- Surface hardening characterization

- Online characterization of rolled steel

- Incoming goods inspection

- Residual, load-induced stress testing, even on integrated components

- Monitoring and recurring inspections (early detection of thermal aging, neutron embrittlement, fatigue, creep damage, stress change)

- Material characterization with high spatial resolution

Benefits

- Fast, nondestructive testing of material characteristics up to a depth of 5 mm

- Simultaneous determination of multiple quality parameters

- Continuous monitoring and documentation of quality parameters

- Increase of the inspected production volume; more cost-effective production by cost reduction

- Integrated process monitoring

- Custom implementation to meet special requirements (test probe design, software)

Flyer “Micromagnetic materials characterization with 3MA-II, 3MA-X8 and BEMI“

Fraunhofer Institute for Nondestructive Testing IZFP

Fraunhofer Institute for Nondestructive Testing IZFP